Posted on Sunday, September 22, 2024

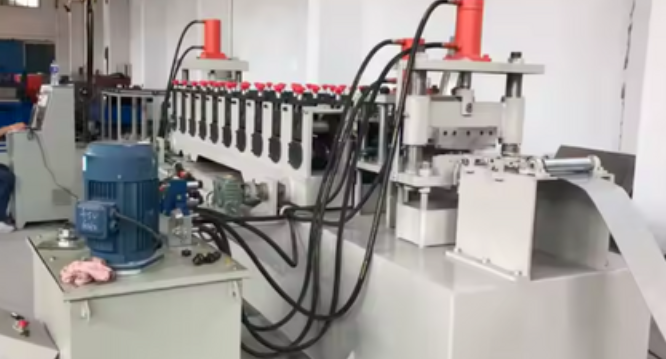

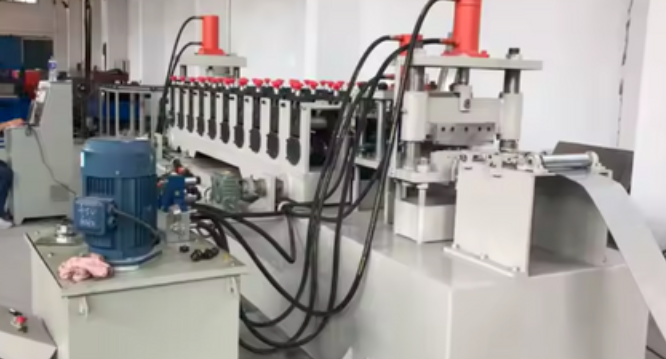

Here are the main components typically found in a roll forming machine:

Each of these components works together to create the desired metal profile in roll forming machines for various products, such as roof panels, structural profiles, or specific designs like standing seam panels.

Greenhouse Profile Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 18, 2026

Precision Roll Forming Machines for Agricultural & Greenhouse Structural Profiles

Traffic Signal Pole Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 18, 2026

Heavy-Duty Roll Forming Machines for Traffic, Lighting & Utility Pole Systems

Container Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 18, 2026

Heavy-Duty Roll Forming Machines for Shipping Container & Modular Structure Panels

Fence Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 18, 2026

Precision Roll Forming Machines for Security, Perimeter & Fencing Systems

Copyright 2026 © Machine Matcher.