These controls can be manual, semi-automatic, or fully automatic, depending on the machine's complexity and the application's requirements. Here are the key components and features of roll forming machine controls:

1. PLC (Programmable Logic Controller):

- Description: A digital computer used for automation of electromechanical processes, such as control of machinery.

- Function: PLCs handle input/output (I/O) signals, control the sequence of operations, and can be programmed for different roll forming profiles.

- Use: Manages the overall machine operation, controlling the forming speed, cutting cycles, and more.

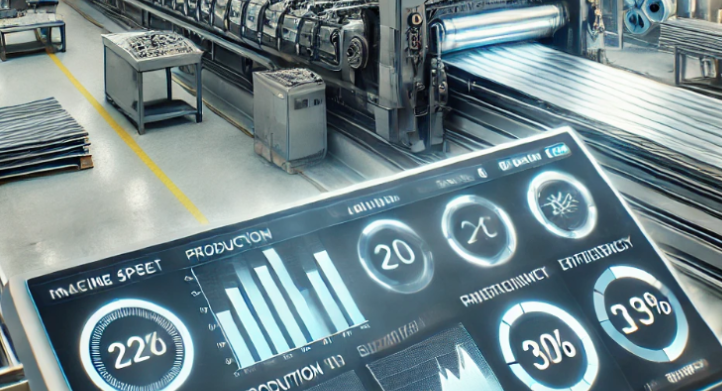

2. HMI (Human-Machine Interface):

- Description: A user-friendly interface that allows operators to interact with the machine.

- Function: Displays machine data, allows manual or automated control, and provides options for diagnostics and adjustments.

- Use: Input roll forming parameters such as material length, cut lengths, and profile changes.

3. Speed Control:

- Description: Controls the speed of the rollers during the forming process.

- Function: Adjusts the roll forming speed based on the material being used and the required profile.

- Use: Allows the operator to increase or decrease the forming speed for optimal performance.

4. Cutting System Control:

- Description: Manages the operation of the cutting mechanism at the end of the roll forming line.

- Function: Ensures precise cutting of the material to the correct length.

- Use: The system is often integrated with length sensors and can be adjusted to match different cutting requirements.

5. Length Encoder/Sensor:

- Description: A device that measures the length of the material passing through the roll forming machine.

- Function: Provides feedback to the PLC to ensure precise cutting after forming.

- Use: It helps achieve accurate lengths of formed products by controlling the cutting mechanism.

6. Servo Motors:

- Description: Motors that precisely control movements of the roll forming machine.

- Function: Used for accurate positioning, smooth operation, and speed regulation.

- Use: These motors control the roll stands, cutters, and other mechanical parts to ensure high precision.

7. Safety Controls:

- Description: Various features designed to prevent accidents or machine damage.

- Function: Includes emergency stop buttons, interlock systems, and overload protections.

- Use: Ensures operator safety and machine protection during operation.

8. Diagnostics and Alarms:

- Description: Integrated systems that monitor the machine’s health.

- Function: Provides real-time fault detection and alerts for maintenance issues.

- Use: Ensures continuous and reliable operation by diagnosing and resolving faults early.

9. Profile Memory (for advanced models):

- Description: A feature that allows storing and recalling different roll forming settings for multiple profiles.

- Function: Speeds up the setup process when switching between different product profiles.

- Use: Ideal for machines that handle multiple roll forming profiles.

These controls work together to ensure that the roll forming process is efficient, accurate, and safe.