Posted on Sunday, September 22, 2024

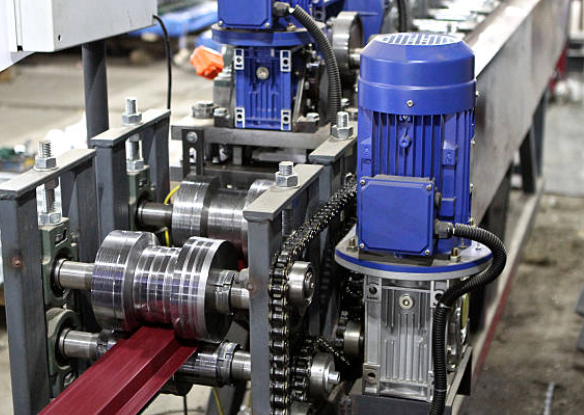

Roll forming machine servicing involves maintenance, repair, and optimization of roll forming equipment to ensure they operate efficiently and prolong their lifespan.

Servicing is essential for various types of roll forming machines such as drip edge roll forming machines, structural machines, tube and pipe machines, and more. Regular maintenance can help avoid costly downtime and ensure that the machines produce high-quality metal profiles. Would you like information on any specific roll forming machine servicing providers or maintenance schedules?

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.