Posted on Monday, September 23, 2024

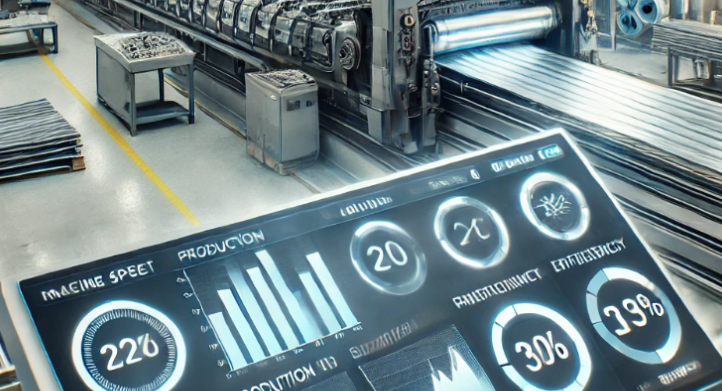

Whether you're a beginner or an experienced operator, training ensures efficient machine usage, safety, and optimal production quality. Key areas of focus during roll forming machine training include:

Training can be conducted on-site by the machine manufacturer or through dedicated courses that focus on roll forming technology.

Machine matcher specialise in matching your roll forming machine requirements with the perfect new or pre owned machine.

We partner with, and represent some of the finest roll forming manufacturers in the market. For more information and a free machine quote please contact us today or view all machines.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.