Posted on Sunday, September 29, 2024

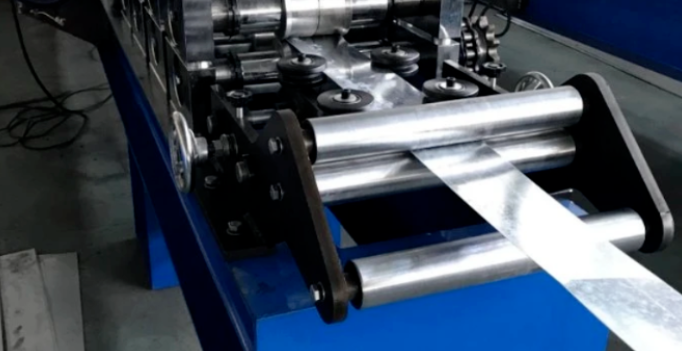

Roll forming machines have become indispensable tools in many industries, offering a range of benefits that improve efficiency, precision, and cost-effectiveness. From metal roofing and structural beams to carports and solar panel mounts, roll forming technology provides versatile and scalable solutions for manufacturers. Let's explore the key benefits of using roll forming machines.

One of the standout advantages of roll forming machines is their ability to produce parts with extreme precision. Whether you’re manufacturing simple or complex profiles, roll forming ensures uniformity across every piece. This level of consistency is especially important for industries such as construction, where exact dimensions and tolerances are crucial for safety and assembly.

Roll forming machines operate at high speeds, allowing for continuous production of metal components without interruption. This speed translates into significant time savings, enabling manufacturers to meet tight deadlines while maintaining product quality. The ability to scale up production quickly helps businesses fulfill large orders more efficiently.

By minimizing waste and reducing material handling, roll forming machines offer a cost-effective production method. The process creates minimal scrap, allowing manufacturers to make the most out of each coil of metal. In addition, the ability to produce parts quickly lowers labor costs, further contributing to cost savings.

From roofing to carports and guardrails, roll forming machines are versatile, capable of creating a wide array of products. Industries such as construction, automotive, and renewable energy rely on roll forming technology to produce everything from structural beams to solar panel mounts. This flexibility makes roll forming a go-to solution for businesses in various sectors.

Roll forming machines can be easily adapted to produce custom shapes and profiles, making them ideal for projects that require non-standard dimensions or unique designs. Whether it's creating specific gutter profiles for a custom roof or producing tailored structural components, roll forming machines offer the flexibility to meet specialized project requirements.

Roll forming machines work with a wide range of materials, including steel, aluminum, copper, and galvanized metals. This versatility in material handling allows manufacturers to choose the best material for each application, ensuring that the final product meets the specific requirements for strength, durability, and corrosion resistance.

Many modern roll forming machines are equipped with advanced automation features, reducing the need for manual labor and minimizing the risk of human error. Automated systems can handle everything from material feeding to cutting, ensuring smooth operation and consistent quality throughout the production line. This not only increases productivity but also helps businesses stay competitive in fast-paced industries.

Roll forming machines are known for their efficiency in material usage, which leads to less waste during production. Moreover, the use of recyclable metals, such as steel and aluminum, makes the process environmentally friendly. As industries increasingly focus on sustainability, the ability to minimize waste and utilize recycled materials gives roll forming machines an edge in eco-conscious manufacturing.

The roll forming process enhances the structural integrity of the metal components being produced. The gradual bending of metal during roll forming adds strength and durability to the finished products, making them suitable for heavy-duty applications such as structural supports, guardrails, and beams.

Roll forming machines are designed for durability, often operating for years with minimal maintenance. Their robust design ensures that they can handle large production volumes over time without a decline in performance, making them a long-term investment for manufacturers.

The benefits of roll forming machines are clear: they provide precision, speed, cost savings, and customization opportunities, all while supporting sustainability efforts. For businesses looking to streamline their production processes and meet growing market demands, investing in roll forming technology is a strategic move that can lead to improved efficiency, product quality, and profitability.

By leveraging these advantages, manufacturers can remain competitive in industries such as construction, automotive, renewable energy, and more. Whether you’re producing structural components, roofing systems, or custom profiles, roll forming machines offer a powerful, scalable solution to meet your needs.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.