Posted on Monday, September 30, 2024

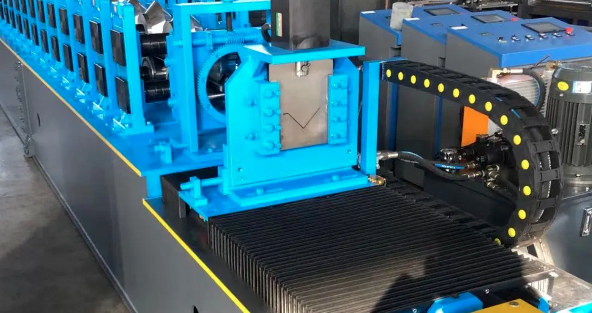

A Drip Edge Roll Forming Machine is a specialized piece of equipment designed to manufacture metal drip edge profiles used in roofing systems. These machines shape metal sheets into precise drip edge profiles, which are critical components installed along the edges of a roof to prevent water from seeping under roofing materials. The drip edge directs water away from the fascia and the underlying structures, helping protect buildings from water damage, rot, and mold.

Overall, a Drip Edge Roll Forming Machine is crucial for the roofing industry, ensuring the efficient and reliable production of metal drip edges that protect buildings from weather-related damage.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.