Posted on Monday, September 30, 2024

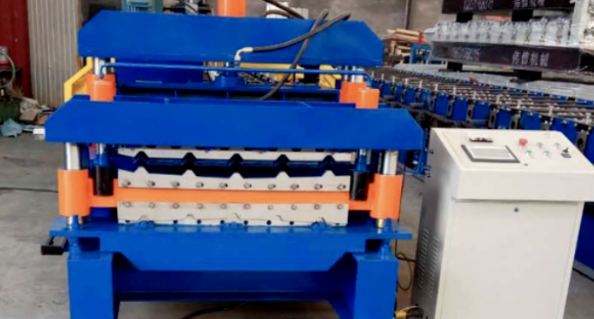

Starting a new business in the roll forming industry can be both exciting and challenging. One of the key decisions you’ll need to make is choosing the right roll forming machine. The right machine can help you scale, optimize your production, and meet your customers' needs. This guide will walk you through key factors to consider when selecting a roll forming machine that aligns with your budget, production requirements, and future growth.

The first step is to assess what kind of products you plan to manufacture. Roll forming machines are highly specialized, meaning different models cater to specific industries and products. Are you focusing on roofing panels, purlins, metal decking, or something else? Knowing your target products will help narrow down machine options.

Budget is a key consideration, especially for new businesses. There are different price ranges for roll forming machines depending on their size, capability, and automation features. While high-end machines may offer more automation and faster production speeds, they can also come with a higher upfront cost. Startups should balance between affordability and future scalability.

As a new business, scalability should be a top priority. Your chosen roll forming machine should have the capacity to grow alongside your business. Look for machines that allow for expansion, such as adding new tooling or upgrading to faster production speeds.

Automation can significantly enhance production efficiency and reduce labor costs, which is important for new businesses. Machines with automated setups, pre-programmed controls, and quick changeovers are excellent for improving efficiency without requiring highly specialized operators.

For a new business, reliable after-sales support is essential to ensure smooth operation and minimal downtime. Choose a manufacturer that offers excellent technical support, training, and access to spare parts.

With growing concerns about sustainability, consider machines that offer energy-efficient production. Some roll forming machines are designed to minimize waste and energy consumption, which can reduce long-term operational costs and make your business more eco-friendly.

Choosing the best roll forming machine for a new business depends on various factors, including your product focus, budget, scalability, and production requirements. Start small but choose a machine that allows you to grow as your business expands. Prioritize automation and ease of use, and make sure you have access to reliable technical support. By carefully considering these aspects, you can make an informed decision that sets your new business up for success.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.