Posted on Friday, September 27, 2024

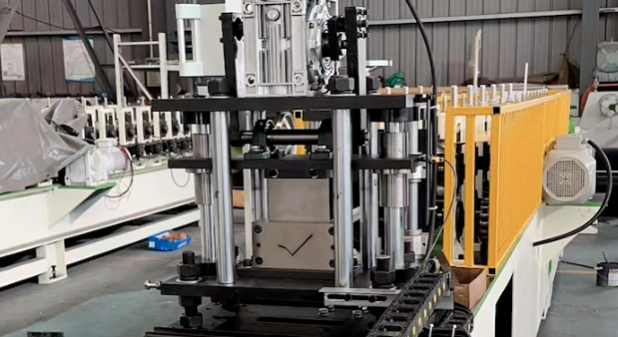

For metal drip edge manufacturers, upgrading or investing in advanced roll forming machines can be a game-changer in terms of both production efficiency and financial returns. Here’s a detailed financial analysis of the return on investment (ROI) when adopting cutting-edge roll forming technology for drip edge production.

The cost of a roll forming machine for metal drip edge production can vary depending on the machine’s capabilities, automation level, and capacity. For instance, a basic machine might cost around $100,000, while a fully automated, high-speed machine could cost upwards of $500,000.

However, the return on this investment becomes apparent through several cost-saving factors:

Investing in a high-speed roll forming machine can significantly boost production capacity, enabling manufacturers to meet growing demand without compromising quality. A basic machine might produce 20-30 feet of drip edge per minute, whereas an advanced machine could easily double or triple that output.

Modern roll forming machines come equipped with advanced controls and precision features that reduce the likelihood of defects in the metal drip edge profiles. Producing consistent, high-quality products reduces the number of returns and reworks, directly impacting the bottom line.

Upgrading to new roll forming machines means less downtime due to maintenance and breakdowns. Modern machines are more reliable, and they often come with predictive maintenance features that alert operators before problems arise. This can reduce downtime by as much as 25-30% compared to older equipment.

In many regions, investments in advanced machinery may qualify for tax incentives, rebates, or accelerated depreciation benefits. For instance, a roll forming machine with a cost of $250,000 may qualify for a tax deduction or depreciation rate of 20%, potentially providing a tax reduction of $50,000 in the first year.

To summarize, let’s assume a manufacturer invests $250,000 in a new roll forming machine. Here’s a breakdown of annual financial benefits:

Total Financial Benefits in Year 1: $445,000

In this example, the total financial benefits of $445,000 in the first year alone greatly exceed the initial investment of $250,000, delivering a return on investment (ROI) of 178% in just the first year. This makes it clear that investing in advanced roll forming machines is not only crucial for improving productivity and product quality, but also for delivering significant financial returns.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.