A Complete Guide to Exporting a Roll Forming Machine: Key Steps, Documentation, and Tips

Exporting a roll forming machine can be a profitable venture, especially given the demand in construction, automotive, and manufacturing sectors globally. However, this process requires detailed planning, understanding of local requirements, and attention to logistics to ensure the machine reaches its destination smoothly and is ready to operate.

A Complete Guide to Exporting a Roll Forming Machine: Key Steps, Documentation, and Tips

Exporting a roll forming machine can be a profitable venture, especially given the demand in construction, automotive, and manufacturing sectors globally. However, this process requires detailed planning, understanding of local requirements, and attention to logistics to ensure the machine reaches its destination smoothly and is ready to operate. This guide outlines the steps and considerations needed to successfully export a roll forming machine.

1. Market Research and Compliance

Before diving into the export process, understanding your target market’s needs and requirements is essential:

- Identify Target Markets: Research countries with a high demand for roll forming machines, such as India, Vietnam, Germany, and Egypt. Analyze the demand for different profile types and determine which markets would benefit most from the profiles your machines produce.

- Understand Export Regulations: Each country has its own import and compliance regulations, which must be strictly followed. For example:

- European countries (like Germany) often require a CE Mark for machinery compliance, verifying that the machine meets the EU’s health, safety, and environmental standards.

- India and Vietnam may have specific import tariffs, which impact the total cost for the buyer.

- Research Egypt’s import policies for equipment, as they often have requirements for machinery quality and may apply customs duties on industrial imports.

- Buyer Preferences: Different countries have varying needs based on construction practices. For example, roofing profiles may be popular in one market, while structural profiles are more in demand in another. Consider profiling needs, dimensions, and thickness requirements common in your target country to ensure the machine meets local expectations.

2. Machine Preparation and Customization

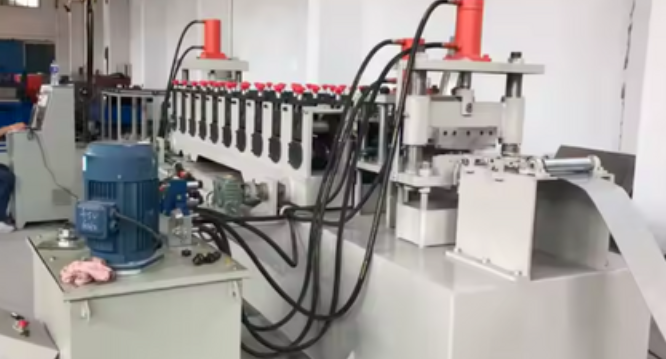

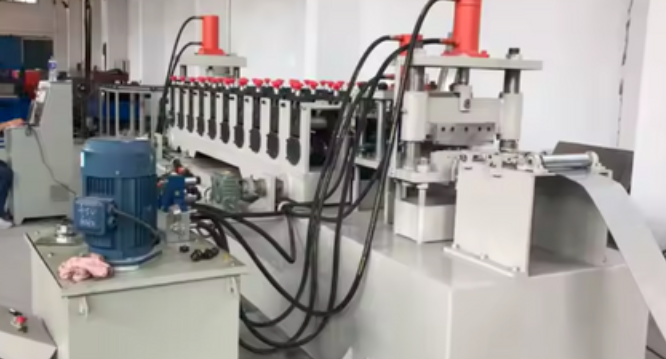

Customizing and thoroughly preparing the roll forming machine for the destination country is a critical step.

3. Documentation and Legal Requirements

Ensuring proper documentation and legal compliance is key to avoiding delays or additional fees at customs.

- Export Documentation: Essential documents include:

- Commercial Invoice: Outlines the machine's value and serves as a bill for the sale.

- Bill of Lading (BOL): A legal document issued by the carrier to confirm receipt of the machine for shipment.

- Certificate of Origin: A certificate proving where the machine was manufactured, which can be helpful for import duty relief in certain countries.

- Warranty and Compliance Certificates: Depending on the country, you may need to provide warranties and compliance certificates, such as the CE mark for European markets or specific certifications for other countries.

- Insurance: Arrange comprehensive insurance for international shipping to protect against potential damage or loss. Marine cargo insurance is generally recommended for long-haul or overseas shipments.

4. Logistics and Shipping

Managing logistics is crucial for the safe and efficient delivery of the machine.

- Choosing a Freight Forwarder: Partner with a reputable freight forwarder experienced in shipping industrial equipment. They can assist with customs clearance, paperwork, and regulatory compliance in the destination country.

- Packaging and Transport: Proper packaging is vital to prevent damage. Roll forming machines are often large and require robust packaging, such as wooden crates with shock absorbers. Ensure that packaging complies with international shipping standards, like ISPM-15 for wood packaging.

- Customs and Import Duties: Familiarize yourself with the destination country's customs and duties. Some countries offer exemptions or reduced duties for industrial machinery, which can be a selling point for buyers.

5. After-Sales Support

Building trust with international buyers often requires excellent after-sales support.

- Installation and Training: Many buyers prefer hands-on support for installation. Offering either remote guidance or arranging for an on-site technician can greatly enhance the buyer’s experience. Providing manuals and video tutorials also adds value.

- Maintenance and Spare Parts: Ensure you provide maintenance options and spare parts availability, as these are essential for the machine's longevity. Offering a maintenance contract or quick shipping of parts can help solidify long-term relationships with international clients.

- Local Partnerships: Where feasible, establish partnerships with local service providers or distributors. This approach can enable quicker response times for repairs or replacements and ease the buyer’s concerns about support and maintenance.

Case Study: Exporting a Roll Forming Machine to Vietnam

Context: A roofing and construction company in Vietnam required a roll forming machine capable of producing metal roofing profiles compatible with local building standards.

Process:

- Customization: The machine was customized to produce specific roofing profiles popular in the Vietnamese market. Additionally, it was adapted to Vietnam’s 220V/50Hz power supply.

- Documentation: Complete export documentation, including a certificate of origin and warranty documentation, was prepared.

- Shipping: The machine was packed in a high-resistance wooden crate to withstand long sea transport, and a freight forwarder familiar with Vietnam’s import policies was selected.

Outcome: The machine arrived in good condition, and the client received remote installation support, which allowed their team to set up and begin operations without delay. Post-sale support was organized through a local distributor, ensuring the client had access to necessary parts and servicing.

Final Thoughts

Exporting a roll forming machine requires detailed planning, local market knowledge, and careful coordination of logistics and after-sales support. By following these steps, you can improve your chances of a smooth export process and build strong relationships with international clients. With demand for roll forming machines on the rise in many countries, tapping into global markets offers promising growth opportunities for your business.