1. Introduction

- The roofing industry in Nigeria is booming, with demand driven by both urban development and infrastructural projects. However, to meet this demand efficiently, companies need reliable, high-quality equipment. NigerRoof Innovations Ltd. has emerged as a leading provider of roofing solutions in Nigeria, known for its quality, durability, and commitment to locally sourced products.

2. Initial Challenges

- High Demand and Production Gaps: Despite a high demand for roofing profiles in Nigeria, NigerRoof Innovations Ltd. struggled with limited production capabilities.

- Dependency on Imported Profiles: Importing profiles led to high costs and delays, affecting the company’s bottom line.

- Power Supply Issues: Nigeria’s inconsistent power supply made it difficult to maintain stable production.

- Maintenance and Downtime: Machines frequently broke down due to Nigeria’s hot and dusty environment, leading to extended downtime and lost revenue.

3. Machine Selection Process

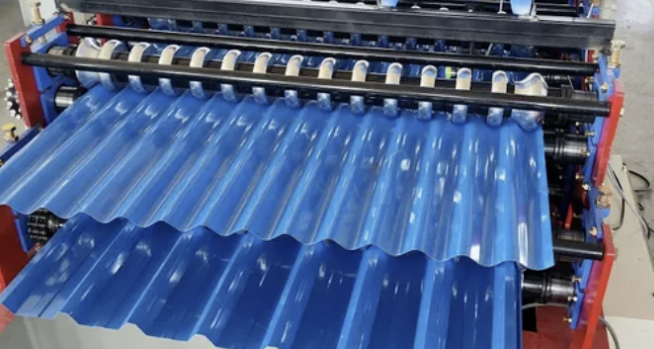

- Research and Evaluation: NigerRoof Innovations Ltd. researched various roll forming machines to identify one that offered durability, customization, and adaptability.

- Key Selection Criteria:

- Adaptability to Power Conditions: Machines capable of operating on alternative power sources, such as generators.

- Customizable Profile Production: The ability to produce various roofing profiles for diverse market demands.

- Durability and Ease of Maintenance: Machines designed to withstand Nigerian environmental conditions, reducing maintenance frequency.

- Choosing the Right Supplier: After careful consideration, NigerRoof Innovations Ltd. selected a reputable supplier experienced in customizing machinery for the African market, securing long-term post-purchase support.

4. Customizations for Nigerian Conditions

- Power Supply Adaptations: The machine was adapted for easy switching between mains electricity and generator power, minimizing downtime.

- Climate-Proof Modifications: Dust-resistant seals were installed to prevent clogging and overheating, making the machine resilient in dusty conditions.

- Enhanced Training Programs: The supplier provided specialized training to NigerRoof’s workforce, enabling effective maintenance and operation of the new machines.

5. Implementation and Outcomes

- Increased Production Capacity: Within six months, NigerRoof Innovations Ltd. saw a 50% increase in roofing profile production.

- Cost Savings: Producing locally reduced dependency on imports, cutting costs by 20% and allowing for more competitive pricing.

- Reduced Downtime: Maintenance costs dropped by 30%, and downtime was halved, thanks to the machine’s rugged design.

- Market Expansion: With increased efficiency, NigerRoof Innovations Ltd. expanded into new regional markets across Nigeria, boosting its market share by 15%.

6. Customer Impact and Market Reach

- Improved Product Quality: Enhanced production processes resulted in higher-quality profiles, elevating customer satisfaction and reinforcing NigerRoof’s reputation.

- Meeting Market Demand: The company’s increased output allowed it to keep up with Nigeria’s booming construction sector demands.

- Economic Contribution: NigerRoof’s success fostered local economic growth by creating jobs, reducing import reliance, and supporting Nigerian-made products.

7. Conclusion

- By choosing the right roll forming machine and adapting it to local conditions, NigerRoof Innovations Ltd. transformed its production capacity and operational efficiency. This case study demonstrates the value of investing in quality, tailored machinery to meet the unique demands of the Nigerian market.

This case study illustrates how NigerRoof Innovations Ltd. successfully overcame industry challenges, positioning itself as a leading roofing profile manufacturer in Nigeria’s market. It offers insight for other manufacturers considering similar investments in tailored machinery for local success.