Posted on Tuesday, October 1, 2024

C6 Style Drip Edge Profile .png file | 557 KB

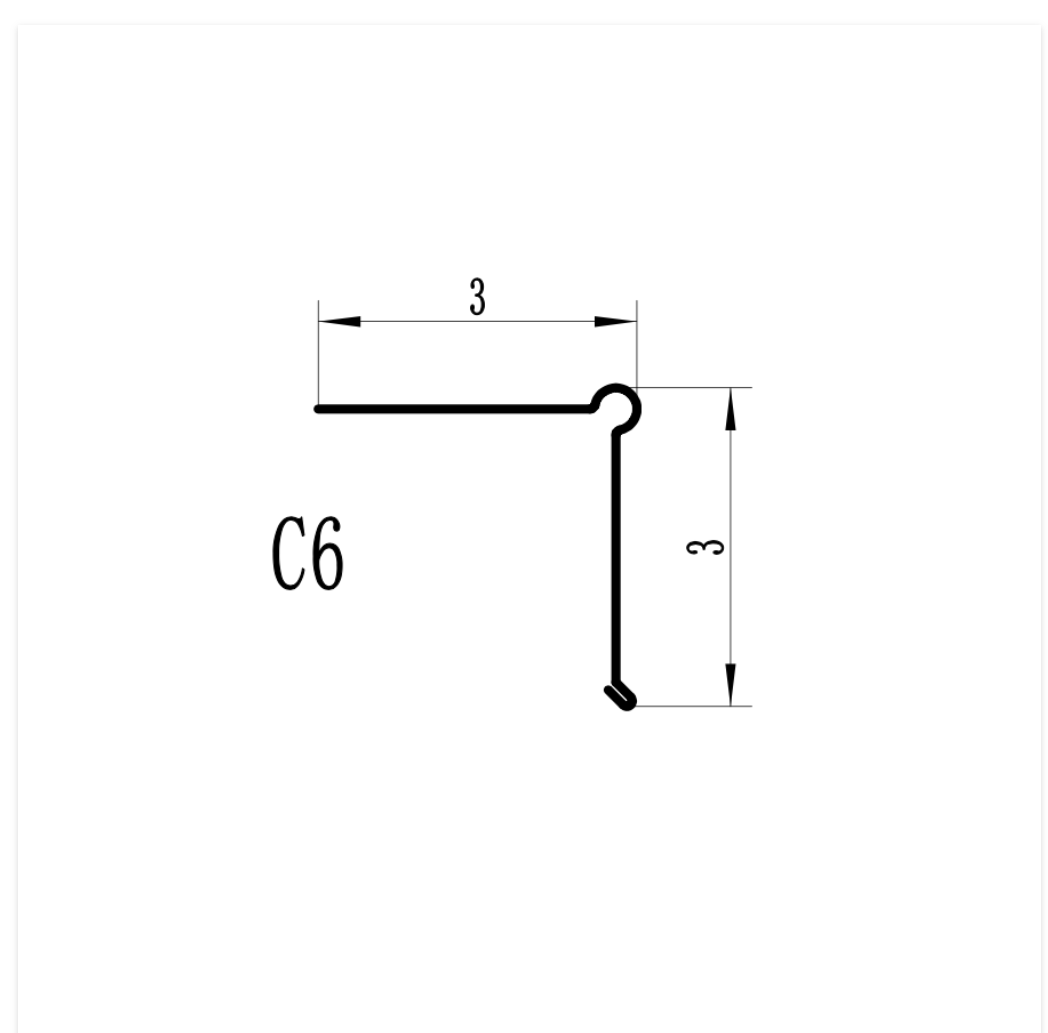

The C6 Style Drip Edge profile is a popular design used in roofing applications to guide water away from the roof and prevent water damage to underlying structures. It typically features a sharp bend at the top edge to provide a clean finish that sits flush against the roof. This profile helps protect the fascia board and roof deck from moisture infiltration.

The C6 style can be used in both residential and commercial roofing projects, offering durability and an aesthetically pleasing finish. It is often made from metal materials like aluminum, galvanized steel, or copper, depending on the roofing needs.

If you're looking for specific dimensions or need customization, it would typically involve the height of the vertical leg, the width of the overhang, and any additional features like hems or stiffening ribs for added strength. Do you need detailed specifications or a machine recommendation for producing this profile?

A C6 Drip Edge Roll Forming Machine is specifically designed to produce the C6 style drip edge profile, commonly used in roofing systems. This machine can manufacture the precise bends and angles needed for the C6 drip edge, ensuring high efficiency and consistent output. Key features of a C6 drip edge roll forming machine include:

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.