Posted on Thursday, October 3, 2024

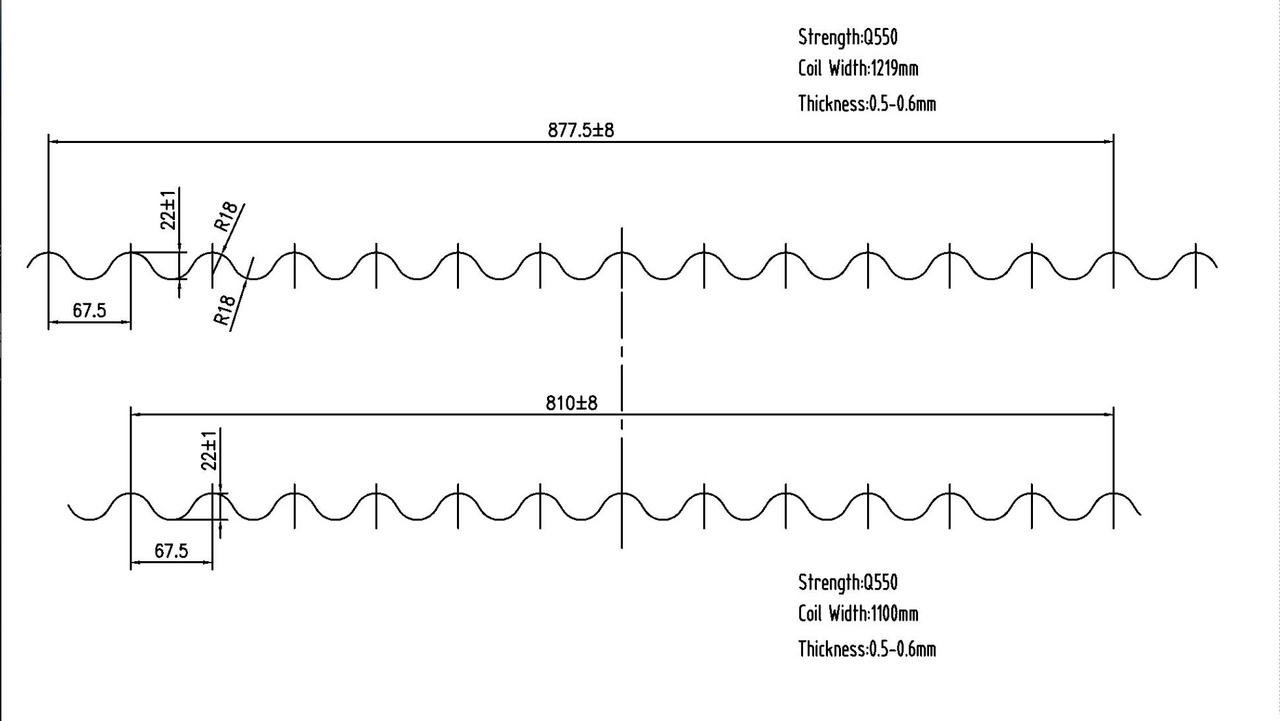

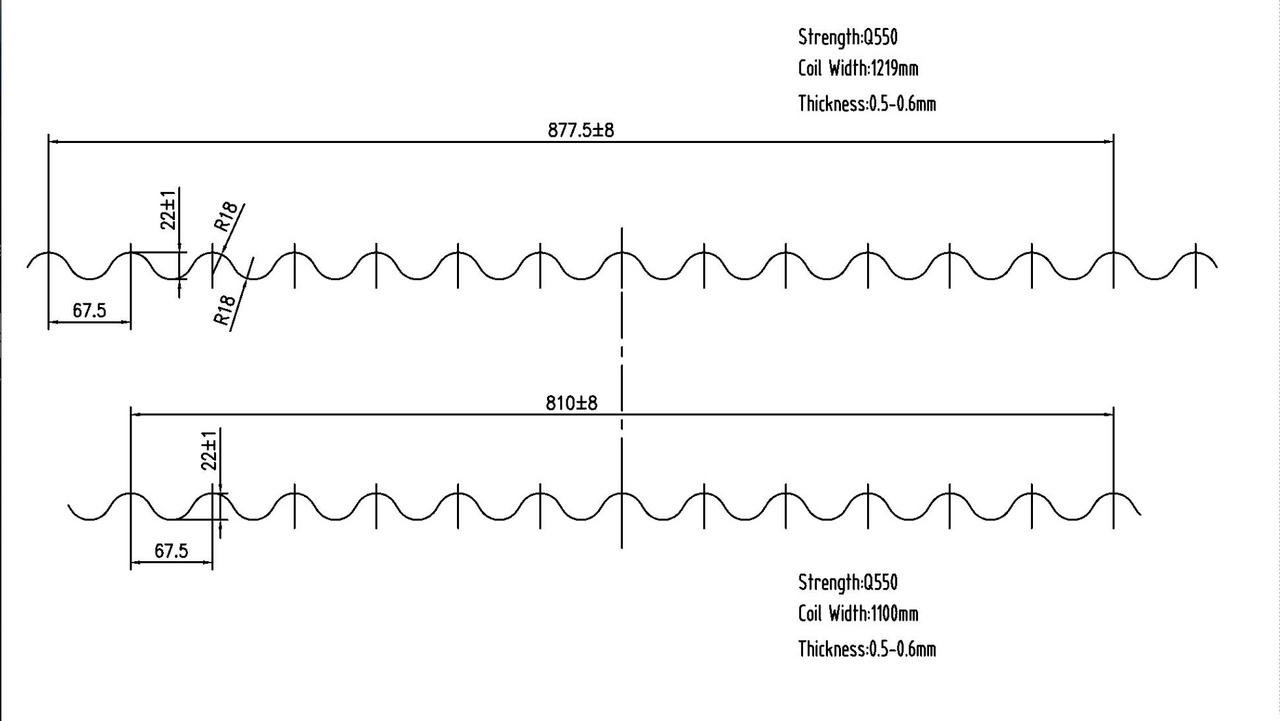

A corrugated panel roll forming machine produces metal panels with a wavy or "corrugated" profile, commonly used for roofing, siding, and cladding applications due to their durability and structural strength. These panels are particularly favored in industrial, agricultural, and residential buildings.

These machines typically use a continuous coil of metal, which is fed through a series of rollers designed to bend the metal into the desired corrugated shape, allowing for high-speed and efficient production.

Would you like more technical details or information on purchasing options for this type of machine?

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.