Posted on Tuesday, October 1, 2024

F4 Style Drip Edge Profile .png file | 593 KB

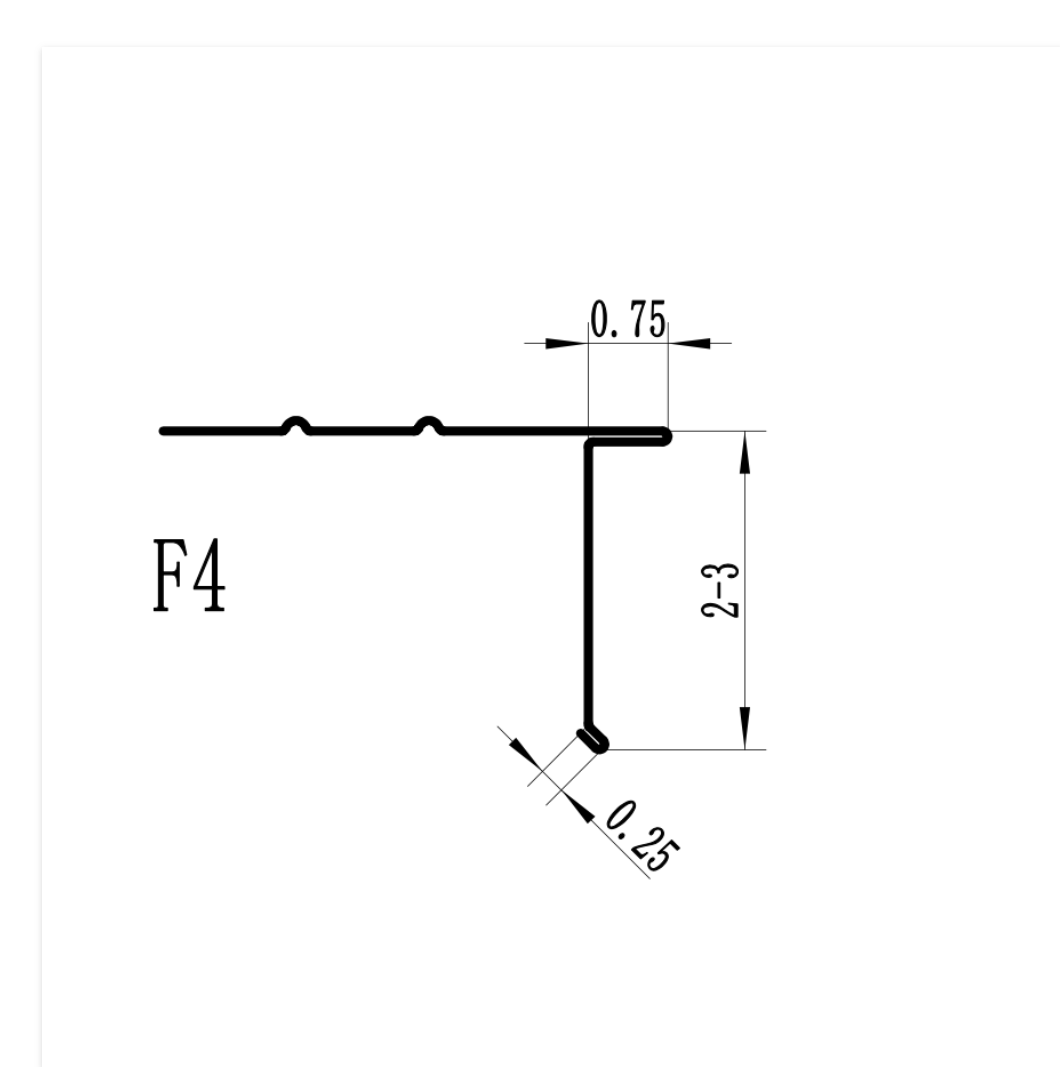

The F4 style drip edge profile is a common roofing accessory used to direct water away from the fascia and protect the roof's underlying structure from water damage. It typically has a wider face compared to standard drip edge profiles, offering greater protection.

In detail, the F4 style drip edge features:

This style is popular in residential roofing applications, particularly in regions prone to heavy rainfall or snow, where additional protection is required for water runoff.

An F4 roll forming machine is designed to produce F4-style drip edge profiles commonly used in roofing applications. These machines are typically highly specialized, allowing for precise shaping of metal coils into the desired F4 drip edge profile, with a wider face and a drip lip that directs water away from the fascia.

If you're considering purchasing an F4 drip edge roll forming machine, it would be ideal to explore options that offer fast changeover times, robust construction, and easy maintenance to keep up with production needs.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.