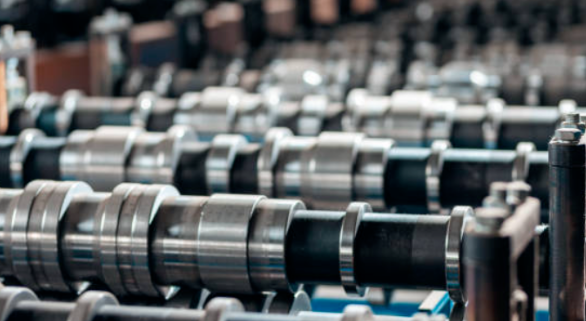

Maintaining roll tooling in a roll forming machine is crucial for ensuring consistent production quality and extending the life of your equipment. However, even with regular maintenance, there comes a time when tooling must be replaced. Below, we’ll explore the key signs that it’s time for new roll tooling and the best maintenance practices to keep your roll former running smoothly.

Signs It’s Time for New Roll Tooling

- Inconsistent Product Quality

If you notice variations in the profiles being formed, such as uneven edges, dents, or waviness, it may be time to inspect the roll tooling. Tooling that is worn or damaged can lead to inaccurate forming, affecting the overall product quality. - Visible Wear and Tear

Roll tooling is subjected to significant wear during production, especially when working with harder metals or high-volume production. Inspect your tooling regularly for visible signs of wear, such as flattening, chipping, or pitting on the roll surfaces. - Increased Downtime

Frequent machine breakdowns or the need for constant adjustments may indicate that the roll tooling is nearing the end of its useful life. Worn tooling can cause excessive strain on the machine, leading to operational inefficiencies and costly downtime. - Excessive Material Waste

If you’re noticing an increase in scrap material or rejected parts, this could be a sign that the tooling is no longer forming metal accurately. This waste can add up over time, making new tooling a cost-effective solution to improve efficiency. - Vibrations or Unusual Noises

Abnormal vibrations or noises during operation can indicate that the tooling is no longer aligned properly or has become damaged. This can affect both the tooling and the machine itself, leading to bigger issues if not addressed promptly.

Best Practices for Roll Former Maintenance

- Regular Tooling Inspections

Conduct routine inspections of the roll tooling to identify any early signs of wear or damage. Addressing small issues early can prevent larger problems and extend the life of your tooling. - Lubrication and Cleaning

Proper lubrication is essential for smooth operation and reducing wear on tooling and machine components. Keep the machine and tooling clean by removing metal shavings, dirt, and other debris regularly to prevent damage. - Alignment Checks

Periodically check the alignment of the rolls to ensure that they are forming the metal correctly. Misaligned rolls can cause damage to both the tooling and the metal being formed, leading to production inefficiencies. - Sharpen Cutting Blades

If your roll former includes a cutting mechanism, be sure to keep the blades sharp. Dull blades can cause excessive wear on the tooling and reduce the quality of the final product. - Monitor Roll Tension

Roll tension affects how well the metal is formed, and improper tension can lead to defects. Regularly check and adjust the tension to ensure optimal performance. - Establish a Maintenance Schedule

Create and adhere to a preventative maintenance schedule that includes regular inspections, cleaning, and servicing. This will help you catch issues before they become major problems and keep your roll forming machine running efficiently.

When to Replace Roll Tooling

Determining the exact time to replace roll tooling depends on various factors, including the type of materials being formed, production volume, and maintenance practices. As a general rule, if your tooling is causing frequent product defects, increasing downtime, or leading to higher material waste, it’s likely time for replacement.

In conclusion, staying ahead of roll tooling wear and adhering to a strict maintenance routine will not only improve the performance of your roll forming machine but also save you time and money in the long run. Regular inspections, proper lubrication, and timely tooling replacement are key to keeping your production line running smoothly and efficiently.