When choosing a roller door roll forming machine, several key factors should be taken into consideration to ensure it meets your production needs and delivers high-quality results. Here are the most important considerations:

1. Material Type and Thickness

- Material compatibility: Ensure the machine can handle the materials you plan to use, such as galvanized steel, aluminum, or stainless steel.

- Thickness range: The machine should support the thickness of the material you need for your roller doors. This is important for ensuring strength, durability, and performance.

2. Production Capacity and Speed

- Output speed: Check the machine’s forming speed (in meters per minute) to match your production volume requirements.

- Production efficiency: Machines with automated features and minimal downtime will increase efficiency.

3. Profile Design Flexibility

- Customization: Consider if the machine allows flexibility in roller door designs and dimensions (height, width, slats).

- Tooling compatibility: Ensure that the tooling system supports quick changes and adjustments to accommodate different profile designs if necessary.

4. Machine Accuracy and Tolerance

- Precision: The machine should produce components within tight tolerances to ensure consistency and fit.

- Automation for accuracy: Look for CNC-controlled options, which can improve precision in cutting and forming.

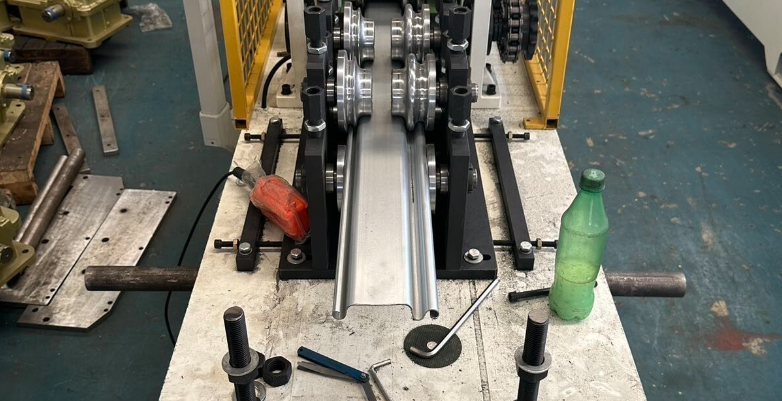

5. Durability and Quality of Components

- Frame and structure: Ensure the machine is made from high-quality materials (like steel or cast iron) to withstand continuous production.

- Rollers and shafts: The rollers and shafts should be hardened and durable, with a focus on long life and minimal wear over time.

6. Control System

- Ease of use: Look for machines with user-friendly control panels or interfaces, preferably PLC or CNC systems that offer automation and ease of operation.

- Software compatibility: Check for machines with programmable software to support customization and updates.

7. Power and Energy Consumption

- Power requirements: Ensure the machine's power requirements match the available infrastructure in your factory.

- Energy efficiency: Opt for machines designed to minimize energy consumption for long-term cost savings.

8. Cutting Method

- Cutting system: Decide whether you need a flying or stationary cutting system based on your production speed and design.

- Cutting accuracy: Ensure the cutting system can deliver precision cuts without deforming the profiles.

9. Maintenance and Spare Parts

- Ease of maintenance: Choose a machine that is easy to maintain with readily available spare parts to reduce downtime.

- Support and service: Ensure the manufacturer provides good after-sales support, including training, spare parts availability, and troubleshooting.

10. Budget and ROI

- Initial investment: Balance the machine’s features with your budget while considering long-term value and return on investment (ROI).

- Financing options: Some manufacturers may offer leasing or financing options to spread out costs.

11. Compliance with Standards

- Industry standards: Ensure the machine complies with safety and quality standards relevant to your industry or region (such as CE or ISO certifications).

12. Space and Layout

- Footprint: Consider the space required for the machine, ensuring it fits your factory layout.

- Workflow integration: Evaluate how the machine integrates into your current workflow and production line.

Considering these factors will help you choose a roller door roll forming machine that meets your production needs, ensuring efficiency, durability, and quality in your output.