Posted on Thursday, October 3, 2024

A Ridge Cap Roll Forming Machine is designed to produce ridge cap profiles for metal roofing systems. The ridge cap is the metal trim that is installed along the peak of the roof, where two roof slopes meet. It plays a crucial role in preventing water from leaking into the roof by covering the joints between the roof panels.

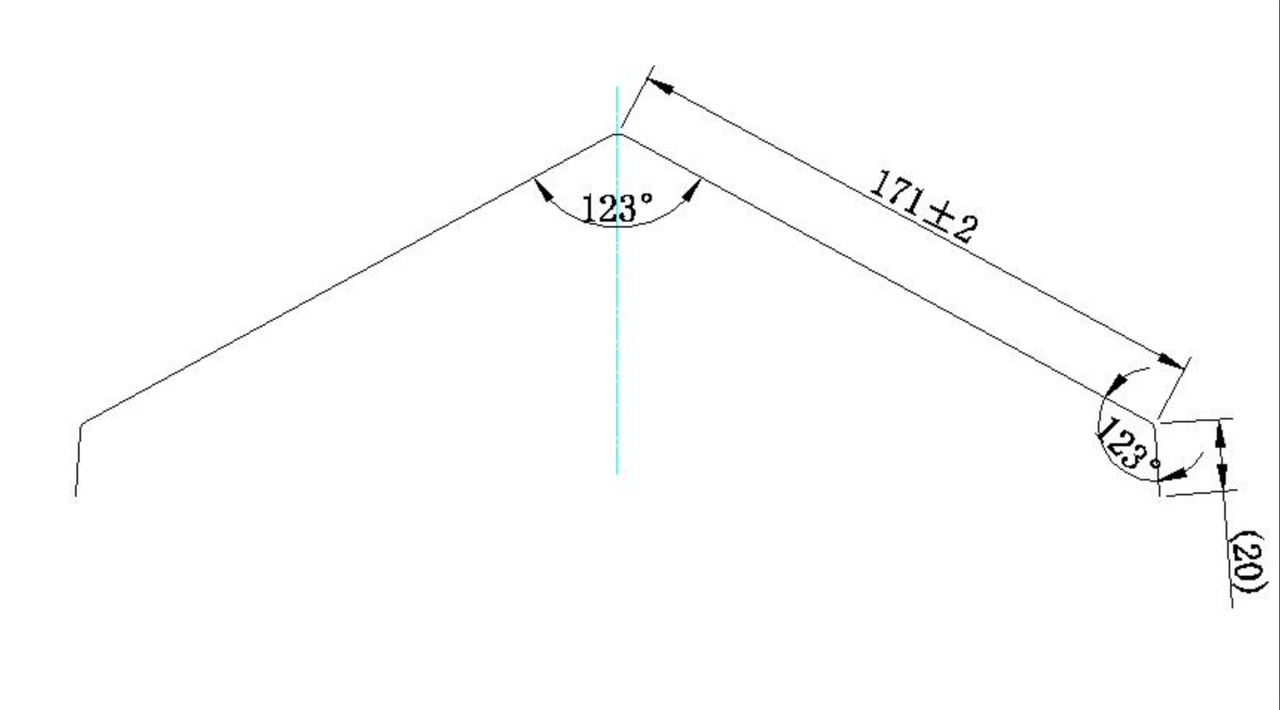

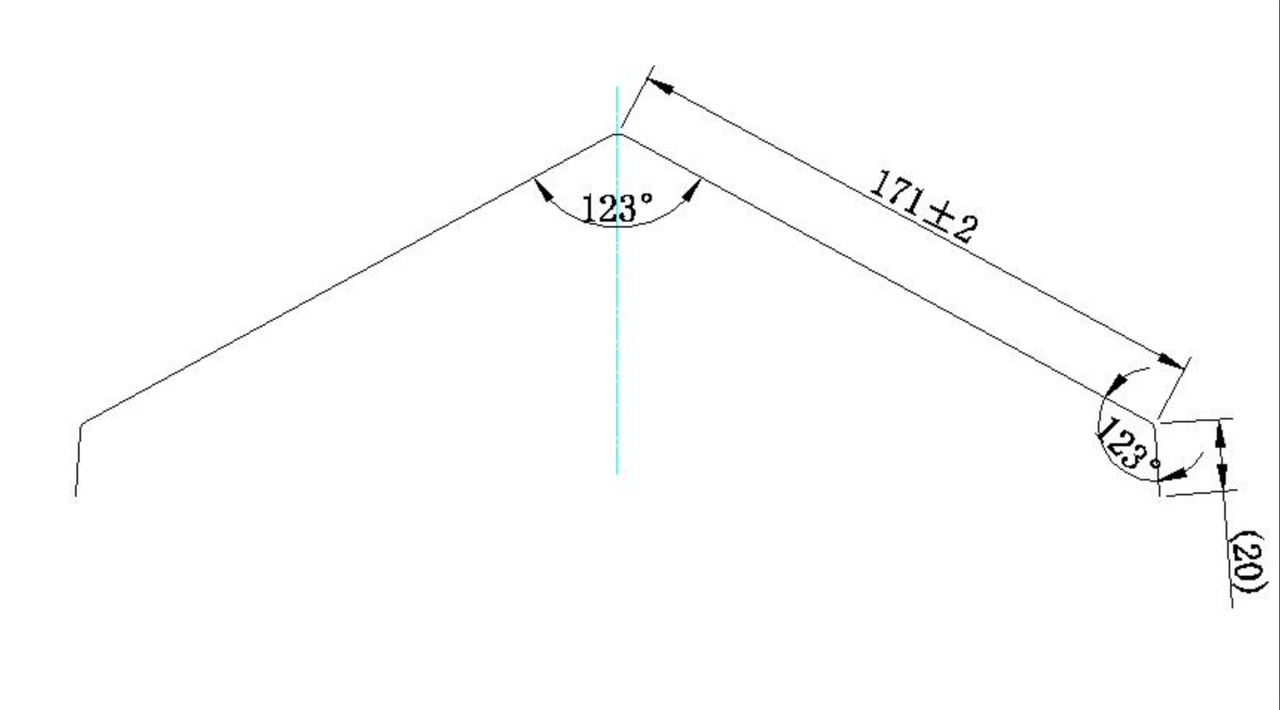

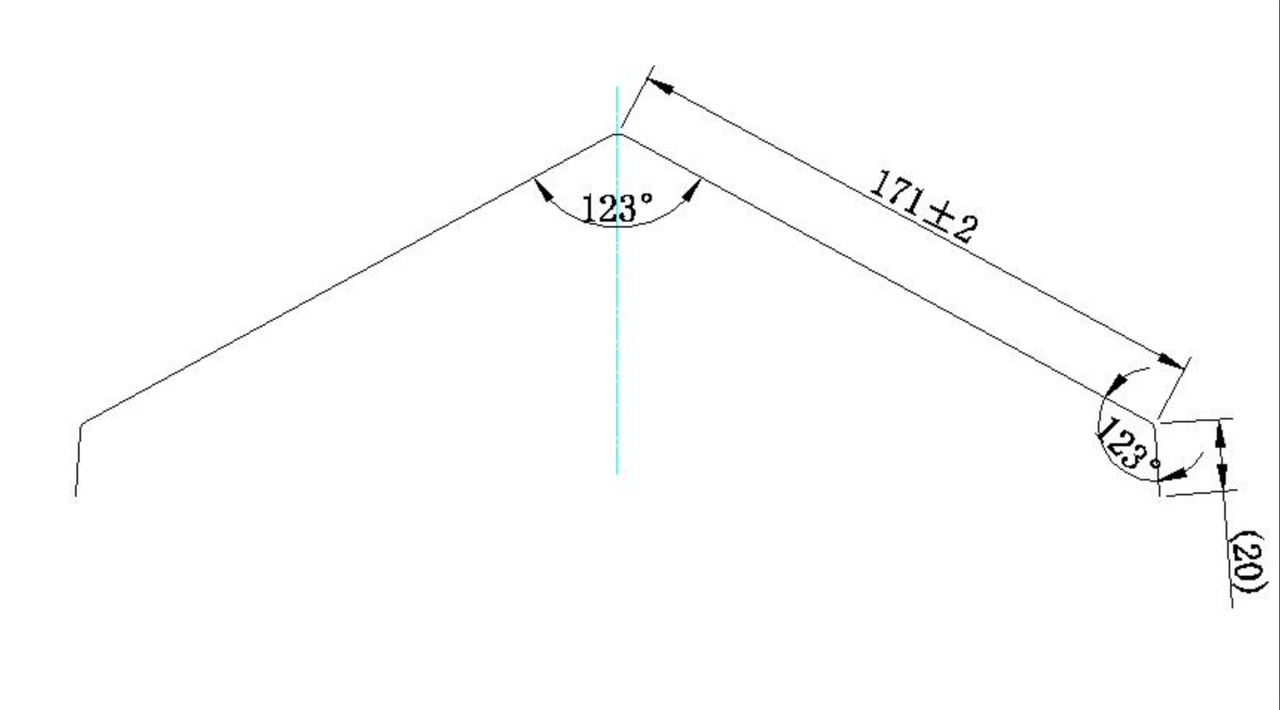

Here is a typical Ridge Cap profile that the machine would produce:

The Ridge Cap Roll Forming Machine uses a series of rollers to shape flat metal coils into this specific profile, ensuring precise bends and consistent quality across the entire production run.

Ridge cap profiles are designed to cover the ridge or peak of a roof where two roof slopes meet, providing a watertight seal while enhancing the roof's appearance. Below are some common ridge cap profiles:

These profiles can be customized based on roof slope, material, and application requirements, with additional features like ribbing or venting slots for improved functionality.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.