Posted on Tuesday, October 8, 2024

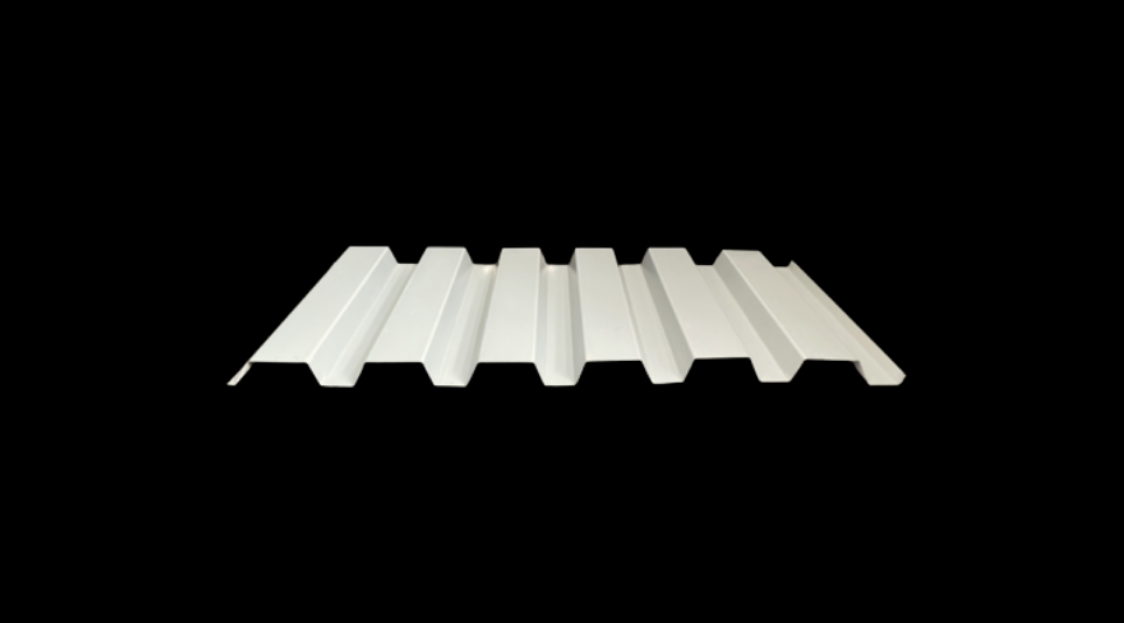

B Deck profiles are versatile structural panels commonly used in roofing and flooring applications for commercial and industrial buildings. These high-strength metal panels are designed to provide excellent load-bearing capabilities and durability, making them a preferred choice for various construction projects.

Design and Features of B Deck Profiles

The B Deck profile features a distinctive shape, characterized by a series of trapezoidal ribs that enhance its structural integrity. This design allows for efficient weight distribution and increased load capacity, making B Decks suitable for both roofing and flooring systems. The depth of the panels, typically ranging from 1.5 inches to 3 inches, contributes to their strength, providing the necessary support for heavy loads while maintaining a lightweight profile.

Manufacturing Process Using Roll Forming Machines

Roll forming machines play a crucial role in creating B Deck profiles. The process begins with flat metal coils, which are fed into the roll forming machine. As the coils pass through a series of rollers, they are gradually shaped into the desired B Deck profile. This continuous process allows for the efficient production of long lengths of B Deck panels, ensuring consistency and quality in each piece.

The roll forming process also allows for customization, enabling manufacturers to produce B Deck profiles with specific dimensions, thicknesses, and coatings to meet project requirements. This flexibility is essential for addressing the diverse needs of commercial and industrial construction.

Applications of B Deck Profiles

B Deck profiles are widely used in various applications, including:

Conclusion

In summary, B Deck profiles are essential components in modern commercial and industrial construction, providing high strength and durability for roofing and flooring systems. The roll forming process ensures that these panels are produced efficiently and consistently, meeting the demands of various construction projects. As the construction industry continues to evolve, B Deck profiles will remain a reliable choice for building professionals seeking quality and performance.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.