Posted on Wednesday, October 9, 2024

A drip edge profile is a crucial component in roofing systems, designed to guide water away from the edges of the roof and prevent it from infiltrating the underlying structures of a building. Typically made from metal, drip edges are installed along the eaves and rakes of the roof to create a protective barrier that enhances the roof's performance and longevity.

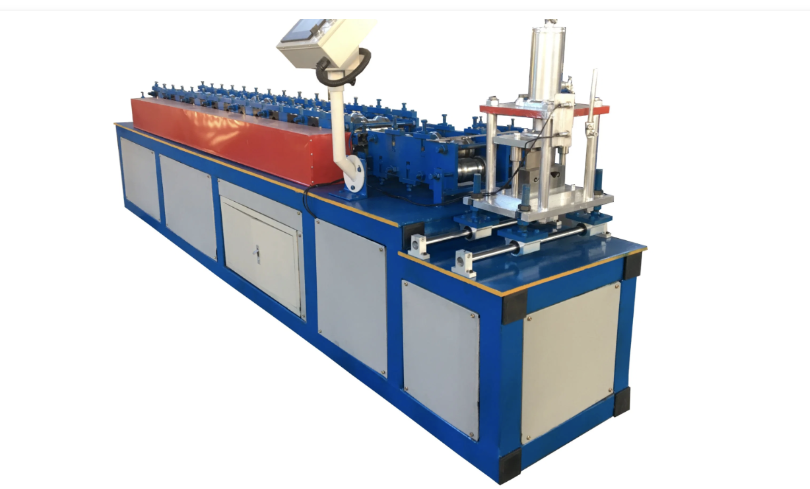

Roll forming machines are integral in the manufacturing of drip edge profiles due to their efficiency, precision, and ability to produce long runs of uniform products. Here’s how they contribute to the production process:

In summary, drip edge profiles play a vital role in protecting buildings from water damage and enhancing the durability of roofing systems. Roll forming machines enable the efficient production of these essential components, ensuring high quality and customization to meet the needs of various roofing projects.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.