Posted on Thursday, October 3, 2024

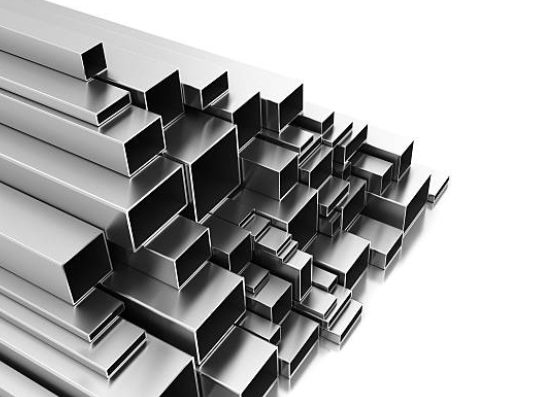

A square tube profile is a type of hollow structural section (HSS) with a square cross-section. It is commonly made from metal, typically steel or aluminum, and is known for its strength, rigidity, and versatility. Square tubes are widely used in construction, manufacturing, and framing due to their ability to bear significant loads while maintaining a relatively lightweight structure.

Square tube profiles are utilized in a variety of structural and non-structural applications:

Roll forming machines are essential in manufacturing square tube profiles. The process starts with a flat metal strip or coil, which is fed into the roll forming machine. The machine has a series of precisely aligned rollers that gradually shape the metal into the desired square profile through continuous bending. Key steps include:

The roll forming process ensures that square tube profiles are consistent in size and shape, allowing for tight tolerances and uniformity across large production runs. These tubes are durable and versatile, making them suitable for various construction and industrial projects.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.