Posted on Tuesday, October 8, 2024

Roll forming is a sophisticated manufacturing process that creates various metal profiles by continuously bending a flat strip of metal into specific shapes. Among the many profiles produced through this method, tubing profiles play a vital role across several industries, including automotive, construction, and industrial applications. This blog explores what tubing profiles are, how they are made, and their significance in various sectors.

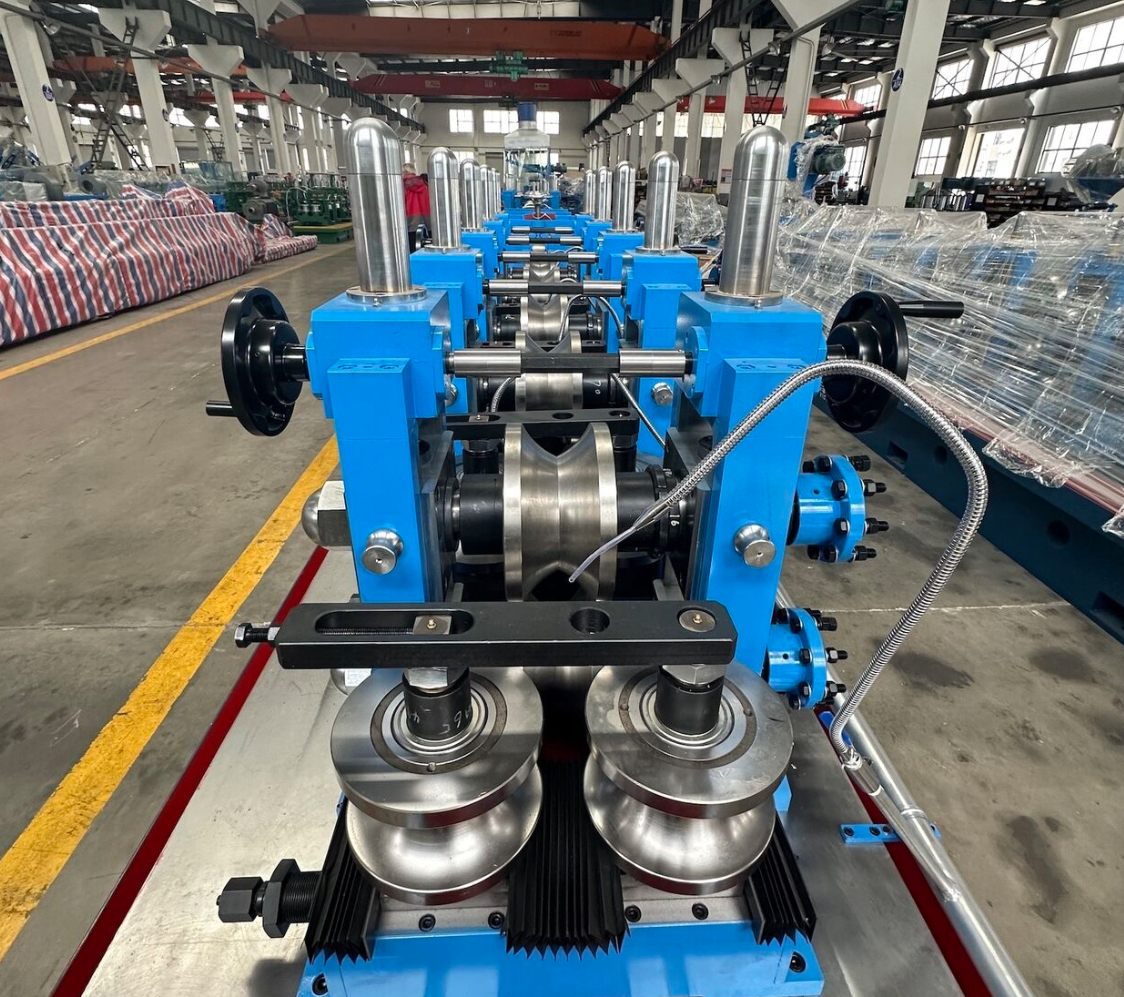

In the context of roll forming, a tubing profile refers to a hollow metal shape created by bending and forming a strip of metal into a tube-like structure. This process typically involves a series of rollers that gradually shape the metal strip into the desired profile, which can vary in shape, size, and thickness. The result is a consistent and durable tubing profile that can be used for a wide range of applications.

Roll forming machines can produce various tubing profiles, each tailored to specific needs. Some of the most common types include:

1. Automotive Sector

Tubing profiles are crucial in the automotive industry, where they are used to manufacture vehicle frames, supports, and various components. The lightweight yet strong nature of roll-formed tubing allows for more efficient vehicle design, contributing to improved fuel efficiency and performance. Furthermore, the precision of roll forming ensures that each component meets the stringent safety and quality standards required in automotive manufacturing.

2. Construction Industry

In construction, tubing profiles serve as structural framing, scaffolding, and support elements. Their durability and strength make them ideal for a wide range of building projects, from residential homes to commercial structures. Roll-formed tubing profiles can withstand various environmental stresses, ensuring longevity and safety in construction applications.

3. Industrial Applications

The industrial sector relies heavily on tubing profiles for manufacturing equipment, conveyors, and machinery frames. The strength and stability of roll-formed tubing make them suitable for demanding industrial environments, where equipment must endure heavy use and potential wear and tear. Additionally, the cost-effectiveness and reduced material waste associated with roll forming enhance the overall efficiency of industrial operations.

Tubing profiles produced through roll forming play a significant role in multiple sectors, including automotive, construction, and industrial applications. Their versatility, durability, and cost-effectiveness make them an ideal choice for manufacturers and contractors looking to meet specific project needs. As the demand for high-quality metal components continues to grow, roll forming will remain a vital manufacturing process, enabling innovation and efficiency across various industries.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.