Posted on Wednesday, October 9, 2024

The best type of drip edge depends on several factors, including the climate, roofing materials, and the specific needs of the project.

For most residential and commercial projects, aluminum is the best all-around drip edge material due to its balance of durability, corrosion resistance, and cost-effectiveness. Galvanized steel is excellent for extreme climates, while copper is ideal for premium, aesthetic installations. The choice will depend on budget, climate, and the architectural style of the project.

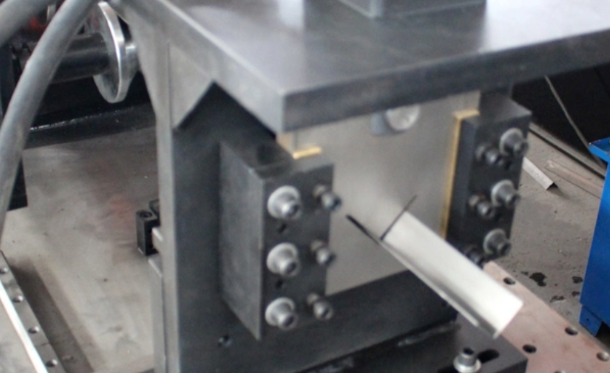

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.