Posted on Friday, October 18, 2024

The main difference between C-style and F-style drip edge lies in their design and application, primarily related to how they manage water runoff at the edges of a roof.

In summary, C-style is simpler and used for basic applications, while F-style offers more support and is ideal for roofs with overhanging shingles or where additional reinforcement is required.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

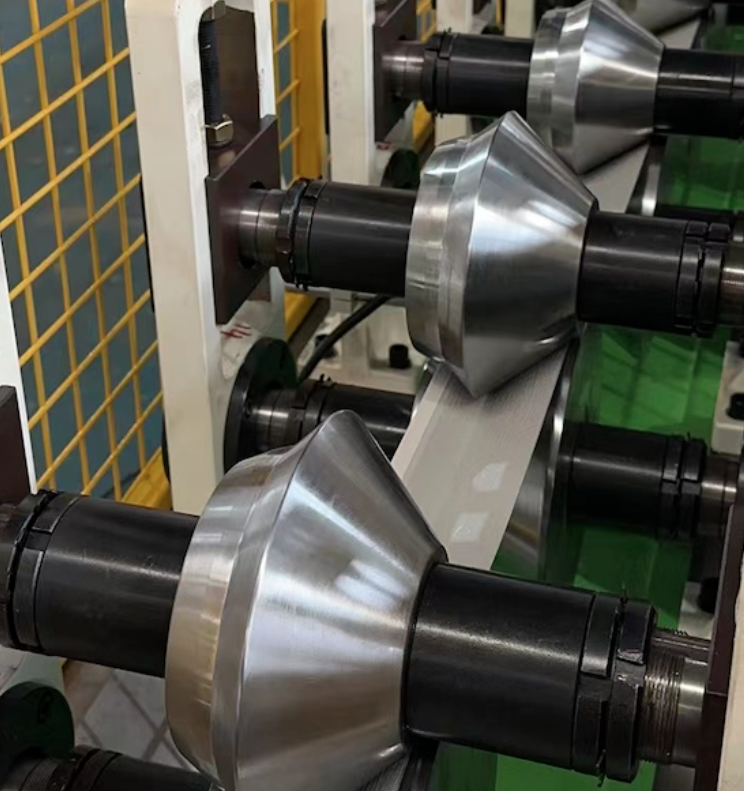

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.