Posted on Sunday, October 6, 2024

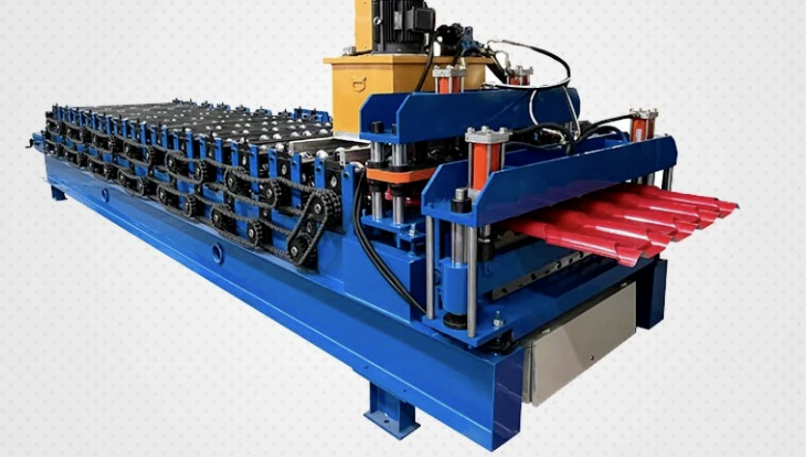

When considering an investment in roll forming technology, one of the critical decisions manufacturers face is whether to choose a single-profile or a multi-profile roll forming machine. Each type has its unique advantages and applications, making it essential to understand the differences to ensure the right fit for your production needs.

Definition and Functionality: Single-profile roll forming machines are designed to produce one specific profile consistently. Once set up for a particular design, the machine operates with high efficiency, producing large volumes of the same product without interruption.

Advantages:

Best Suited For: Single-profile machines are ideal for manufacturers who have a steady demand for a particular product, such as roofing panels, gutters, or specific structural components, where high volume and consistency are paramount.

Definition and Functionality: Multi-profile roll forming machines are versatile systems that can produce multiple profiles by adjusting the tooling and settings. These machines allow operators to switch between different designs without extensive downtime.

Advantages:

Best Suited For: These machines are ideal for manufacturers who require adaptability and want to offer a diverse range of products. They are particularly useful in industries like construction, where different profiles may be needed for various projects.

Choosing between a single-profile and a multi-profile roll forming machine ultimately hinges on your business's specific production needs, budget, and market demands. By understanding the strengths and applications of each machine type, you can make an informed decision that aligns with your operational goals and positions your company for success.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.