Posted on Thursday, October 3, 2024

The future of roll forming in smart manufacturing is closely tied to the rise of Industry 4.0 technologies, where IoT (Internet of Things), AI (Artificial Intelligence), and data analytics are revolutionizing the production process. Here's a breakdown of how these technologies are transforming the roll forming industry:

IoT technology allows machines on the factory floor to be interconnected, enabling real-time monitoring of roll forming equipment. Sensors embedded in roll forming machines can track critical parameters like temperature, pressure, and machine speed, offering real-time insights. This helps to predict machine wear, reduce downtime through predictive maintenance, and ensure consistent quality by alerting operators to any deviations in the process.

AI and machine learning algorithms can analyze vast amounts of data from the production process to optimize machine settings and improve overall efficiency. These systems can automatically adjust roll forming machine parameters to enhance material usage, reduce waste, and speed up production without compromising quality. AI can also play a role in predicting future demand, allowing manufacturers to adjust production schedules and materials accordingly.

Smart manufacturing relies heavily on data-driven decision-making. By collecting and analyzing data from the entire roll forming process, manufacturers can identify bottlenecks, improve production line efficiency, and make informed decisions about machine upgrades or maintenance schedules. Advanced data analytics can also help in forecasting market trends, allowing companies to respond proactively to changing customer demands.

The future of roll forming will see even more integration of automation, with robotic systems playing a key role in material handling, loading, and unloading processes. Automation ensures greater precision, reduces the margin for human error, and allows roll forming lines to operate continuously with minimal intervention, enhancing overall productivity.

In smart factories of the future, roll forming machines will be fully integrated into digital ecosystems, where all machines communicate seamlessly with each other. Digital twins (virtual representations of physical machines) could simulate production runs, enabling manufacturers to optimize performance before actual production starts. These connected systems will lead to increased flexibility, allowing manufacturers to quickly switch between different products or adjust specifications on the fly.

In summary, the future of roll forming in smart manufacturing is defined by increased connectivity, intelligent data use, and automation, all working together to create more efficient, flexible, and resilient production processes.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

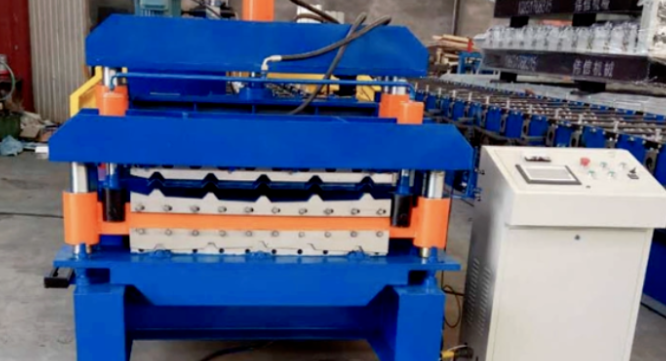

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.