Posted on Tuesday, October 1, 2024

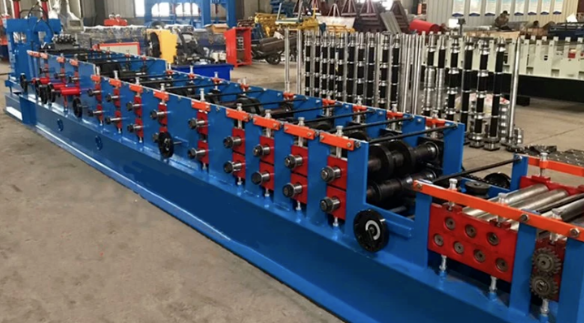

As industries across the globe continue to evolve, the demand for innovative, efficient, and versatile manufacturing processes grows. Roll forming, a continuous bending operation that shapes metal strips into specific profiles, has long been a crucial part of various industries, including construction, automotive, and energy. However, like all manufacturing technologies, roll forming is undergoing a transformation. With advancements in automation, material science, and software integration, the future of roll forming promises to be more efficient, flexible, and sustainable than ever before.

One of the most significant shifts in the roll forming industry is the increasing integration of automation. Traditional roll forming required considerable human intervention, from adjusting machine settings to handling materials. Now, with the advent of fully automated roll forming machines, manufacturers can streamline their operations, significantly reducing labor costs and improving production efficiency.

Automation allows roll forming machines to work continuously with minimal human oversight, ensuring consistent product quality. Advanced sensors and machine learning algorithms enable these machines to self-adjust based on real-time data, minimizing errors and downtime. Predictive maintenance, powered by AI, ensures that machines are serviced before issues arise, further reducing costly interruptions in production.

As automation continues to advance, the role of human workers in roll forming will shift toward oversight, maintenance, and optimization of fully automated systems. This shift will not only increase efficiency but also enhance workplace safety by reducing the need for workers to operate large, heavy machinery manually.

The materials used in roll forming are also evolving. Historically, steel and aluminum were the primary metals used, but new developments in material science are expanding the possibilities for roll-formed products. One notable trend is the increasing use of advanced high-strength steel (AHSS) and other composite materials. These materials offer greater durability, improved performance, and higher strength-to-weight ratios, making them ideal for demanding applications in industries like automotive and aerospace.

Additionally, advancements in coating and finishing techniques are making roll-formed products more resistant to corrosion, wear, and environmental damage. This is particularly important for industries such as construction, where components like roofing panels, structural beams, and siding must withstand harsh weather conditions. As material science continues to evolve, manufacturers will have access to a broader range of high-performance materials, allowing them to produce more robust, long-lasting products.

As with many other industries, digitalization is transforming roll forming. The integration of smart software solutions is enhancing the precision and flexibility of the roll-forming process. Modern roll forming machines are increasingly equipped with advanced control systems that allow for real-time data monitoring and automated adjustments.

For example, digital twin technology allows manufacturers to create virtual models of their roll forming machines and processes. These digital replicas can simulate the production process, identify potential issues, and optimize machine settings for efficiency and precision. This reduces the need for trial and error, minimizing waste and production downtime.

Real-time data monitoring also allows manufacturers to respond quickly to changes in material quality or production conditions, ensuring consistent output. The use of IoT (Internet of Things) devices in roll forming machines enables remote monitoring and predictive maintenance, allowing operators to foresee potential issues and take corrective action before they cause disruptions.

While roll forming excels at producing long, continuous profiles, it has limitations when it comes to creating complex shapes. However, the rise of hybrid manufacturing systems that combine roll forming with 3D printing is opening up new possibilities. By integrating 3D printing technologies, manufacturers can add intricate features to roll-formed parts, creating components that would have been difficult or impossible to produce using traditional roll forming methods alone.

This hybrid approach allows for the production of parts with complex geometries, such as those used in the aerospace or automotive industries, without sacrificing the speed and efficiency of roll forming. As 3D printing technology continues to mature, its integration with roll forming could revolutionize the manufacturing of customized parts.

As industries worldwide place more emphasis on sustainability, the roll forming industry is no exception. Roll forming is already an energy-efficient process compared to other metal forming methods, but the push for greater energy efficiency and waste reduction is leading to even more sustainable practices.

Modern roll forming machines are being designed with energy-efficient motors and systems that minimize energy consumption during production. Additionally, there is a growing trend toward using recycled materials, particularly in industries like construction where environmental regulations are becoming stricter.

By using recycled metals, manufacturers can reduce their carbon footprint and support circular economy initiatives. Roll forming is particularly well-suited to working with recycled materials, as the process minimizes waste and maximizes the use of raw materials.

The future of roll forming technology will not only be shaped by technical advancements but also by the growing demand for roll-formed products in emerging markets. Regions such as Southeast Asia, Latin America, and Africa are experiencing rapid infrastructure development and urbanization, driving demand for roll forming technology to produce construction materials like roofing panels, beams, and studs.

These emerging markets are not just looking for standard products—they are demanding customized solutions that cater to local building codes, environmental conditions, and aesthetic preferences. Roll forming technology, with its ability to produce high-quality custom profiles at scale, is well-positioned to meet this demand.

In regions like Southeast Asia and Africa, renewable energy projects are also on the rise. Roll forming machines are playing a critical role in producing components for solar panel mounting systems, wind turbines, and other energy infrastructure. As global investments in renewable energy continue to grow, the demand for roll-formed components in this sector is expected to increase significantly.

The future of roll forming technology is bright. With advancements in automation, material science, digitalization, and hybrid manufacturing techniques, roll forming is set to become more efficient, flexible, and sustainable than ever before. These innovations will not only benefit established industries like construction and automotive but also open up new possibilities for emerging markets and sectors.

For manufacturers looking to stay competitive, investing in cutting-edge roll forming technology is key. By embracing these trends, companies can enhance their production capabilities, reduce costs, and meet the growing demand for high-quality, customizable metal components across a wide range of industries.

In this rapidly evolving landscape, the future of roll forming will continue to be shaped by the pursuit of efficiency, precision, and sustainability.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.