Posted on Sunday, October 6, 2024

The lifespan of a roll forming machine can vary widely based on several factors, including the machine's quality, the materials used, the operating environment, and the level of maintenance. Generally, here are key considerations regarding the lifespan and maintenance of roll forming machines:

To maximize the lifespan of a roll forming machine, regular maintenance is crucial. Here are some essential maintenance tips:

By understanding the expected lifespan and committing to regular maintenance, potential buyers and users can make informed decisions regarding their investment in roll forming machines. Investing in high-quality machinery and adhering to a robust maintenance schedule can significantly extend the operational life of the equipment, providing better returns and efficiency in production.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

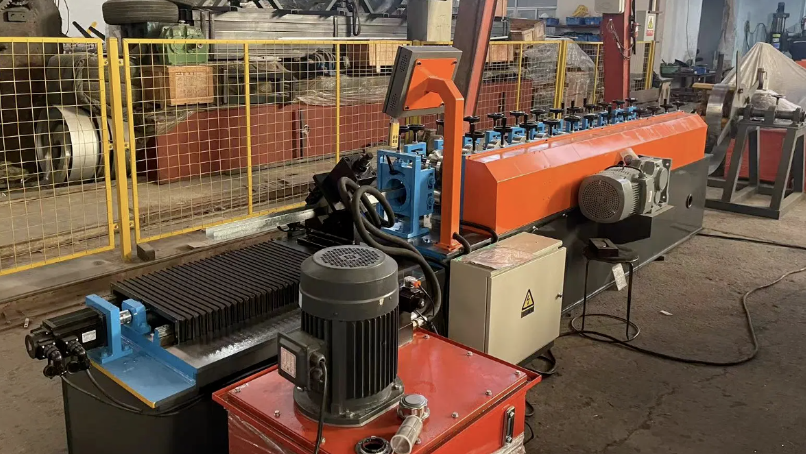

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.