Posted on Wednesday, October 9, 2024

In an era where sustainability and energy efficiency are at the forefront of architectural design, the role of innovative manufacturing techniques is more crucial than ever. Among these techniques, roll forming stands out as a game-changer in the production of building materials. This blog explores how roll forming technology contributes to energy-efficient building designs through the production of insulated metal panels, steel framing, and other essential components.

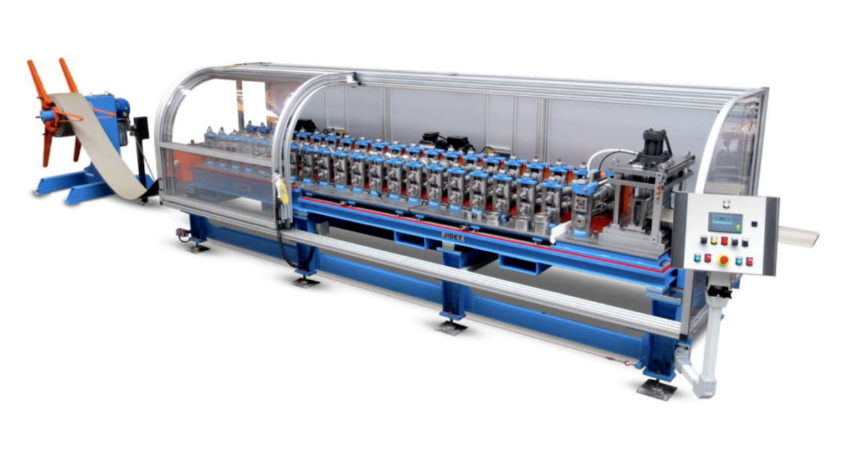

Roll forming is a continuous bending process used to create long lengths of uniform cross-sectional profiles from metal sheets. This method involves feeding metal coils through a series of rollers that gradually shape the material into the desired profile. The advantages of roll forming include its ability to produce high-precision components with consistent quality, reduce waste, and minimize labor costs. As energy-efficient building designs demand more from construction materials, roll forming emerges as a vital player in the industry.

One of the most significant contributions of roll forming to energy-efficient buildings is the production of insulated metal panels (IMPs). IMPs are composed of two metal sheets with an insulating core, providing excellent thermal performance.

Roll forming technology is extensively used to manufacture steel framing components, which are crucial for modern energy-efficient buildings.

One of the key benefits of roll forming is its ability to create customized components tailored to specific building requirements.

Roll-formed materials are often lighter than traditional construction materials, offering several advantages for energy-efficient buildings.

Roll forming technology supports the integration of renewable energy systems into building designs, which is essential for achieving net-zero energy buildings.

Roll forming technology plays a vital role in enhancing energy efficiency in building designs. From producing insulated metal panels that improve thermal performance to creating strong, customizable steel framing systems, roll forming contributes to the sustainable construction practices that are essential in today’s environment. As the demand for energy-efficient buildings continues to grow, the advantages of roll forming will become increasingly important for architects, builders, and manufacturers alike.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.