Posted on Friday, November 1, 2024

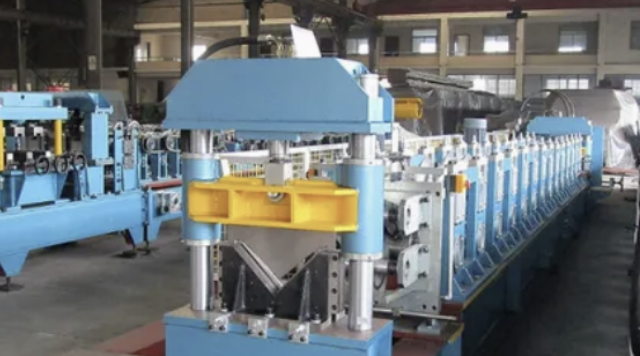

Nigeria’s manufacturing sector is rapidly evolving, with a growing demand for high-quality, durable, and precision-engineered products across various industries, from construction to automotive. In this competitive landscape, manufacturers are looking for ways to increase their production capacity, maintain quality, and reduce operational costs. Roll forming machines are proving to be a powerful asset in this journey. These machines are capable of transforming metal sheets into complex profiles with precision and speed, making them ideal for high-volume production environments. This blog explores how Nigerian manufacturers are using roll forming technology to gain a competitive edge and meet rising market demands.

The demand for roll forming machines in Nigeria is growing as manufacturers seek efficient solutions to scale their production. Industries such as construction, automotive, and agriculture are booming, driven by infrastructure projects, an expanding population, and increased urbanization. Roll forming machines help meet these demands by offering fast, accurate, and cost-effective methods for producing long, continuous shapes used in various applications, such as roofing sheets, panels, and frames.

Some reasons manufacturers are increasingly adopting roll forming machines include:

To maximize the benefits of roll forming technology, Nigerian manufacturers are employing several strategies that allow them to optimize production, reduce downtime, and streamline operations.

Automation is key to increasing production efficiency, and Nigerian manufacturers are embracing it through roll forming systems equipped with automated controls and monitoring systems. Automated roll forming machines minimize the need for manual input, reducing human errors and allowing for continuous production with minimal interruptions. This translates into faster production speeds and lower labor costs.

In Nigeria’s competitive manufacturing landscape, companies are focusing on customization to meet the specific demands of their clients. Roll forming machines can be tailored to produce various profiles, from roofing sheets to metal framing. By working with machine suppliers who understand their specific requirements, manufacturers can configure machines to produce unique profiles that align with market needs. Customization also enables manufacturers to respond quickly to emerging trends and customer demands.

Maintenance is crucial for any machine-intensive operation, and roll forming technology is no exception. Nigerian manufacturers are recognizing the importance of preventive maintenance to avoid costly breakdowns and ensure continuous production. Many companies are implementing regular maintenance schedules and providing training to operators, enabling them to identify and address minor issues before they lead to significant downtime.

Energy costs and supply instability can be challenging in Nigeria, and manufacturers are adopting energy-efficient practices to keep operations cost-effective. Roll forming machines are often equipped with energy-efficient motors and optimized power systems to manage consumption. Additionally, some manufacturers are exploring alternative power solutions, such as backup generators and solar power, to ensure that production can continue even during power outages.

Roll forming machines offer several advantages that are helping Nigerian manufacturers improve their output, reduce costs, and enhance their competitive position.

Let’s look at an example of how roll forming machines have transformed a Nigerian manufacturer’s operations. [Company Name], a leading manufacturer of construction materials, decided to integrate roll forming technology to increase its roofing sheet production capacity. The company chose a fully automated roll forming system that allowed them to triple their production volume within the first year. Additionally, they customized the machine to produce multiple roofing profiles, which enabled them to expand their product offerings and reach new customer segments.

By implementing regular maintenance schedules and training their operators, [Company Name] minimized downtime and maintained a steady flow of production. The investment in energy-efficient equipment also helped them reduce electricity costs, even in the face of Nigeria’s challenging power supply situation. This approach allowed the company to grow its market share, lower production costs, and position itself as a reliable supplier in the Nigerian construction industry.

While roll forming technology offers numerous benefits, there are some challenges and considerations for Nigerian manufacturers to keep in mind.

Although roll forming machines can generate a strong return on investment, the initial purchase and setup costs can be substantial. Many manufacturers are exploring financing options or leasing agreements to make the investment more manageable. Evaluating the expected ROI and choosing a machine with the right capabilities for their business can help manufacturers maximize their investment.

Nigeria’s power supply challenges can impact continuous production. Manufacturers are addressing this by incorporating backup power solutions, such as generators or battery storage, to keep machines running during outages. Some companies are even investing in alternative energy sources, such as solar power, to reduce their reliance on the grid and maintain production efficiency.

Selecting the right supplier is crucial, as manufacturers need machines that meet Nigerian market needs and offer reliable support. Factors to consider include after-sales support, machine warranties, customization options, and the supplier’s reputation. Working with a supplier that understands the unique demands of the Nigerian manufacturing sector can provide a significant advantage.

As Nigeria’s manufacturing sector grows, roll forming machines offer Nigerian companies a powerful way to increase productivity, reduce costs, and stay competitive. By investing in automated, customized, and energy-efficient roll forming solutions, Nigerian manufacturers are expanding their production capacity and meeting the demands of a dynamic market. For businesses looking to expand and excel, roll forming technology is a valuable tool for taking their operations to the next level.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.