Posted on Tuesday, November 12, 2024

Offshore platform construction presents unique challenges that demand high precision, efficiency, and adherence to strict safety standards. Robotic welding systems are transforming this sector by offering innovative solutions that streamline operations and enhance output quality. This blog explores the role of robotic welding in offshore platform construction, the benefits it offers, and its future outlook in marine industries.

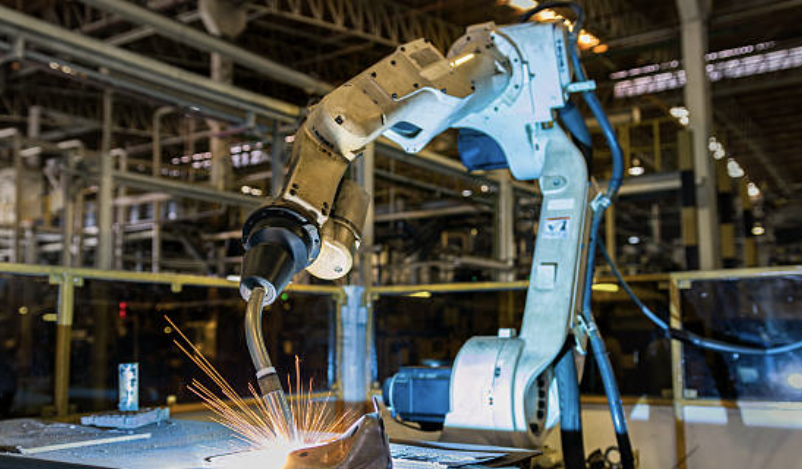

Robotic welding involves the use of automated machines to perform welding tasks with minimal human intervention. In offshore platform construction, these systems weld critical structural components, pipelines, and support beams, ensuring durability in extreme marine environments.

In a recent project for an offshore oil rig in the North Sea, robotic welding systems played a pivotal role in fabricating the platform’s subsea structures. The project involved welding large-diameter pipes under tight deadlines. Robotic systems ensured precise welds even in high-pressure, deep-sea conditions, reducing project completion time by 30% compared to traditional methods.

The marine and offshore industries are increasingly adopting robotic solutions due to their proven efficiency and cost-effectiveness. The global market for robotic welding in marine construction is projected to grow at a compound annual growth rate (CAGR) of 9% over the next decade. Key drivers include:

Major players in the industry are investing in R&D to develop next-generation robotic systems tailored for marine applications.

Q: What are the main challenges of welding in offshore construction?

A: Offshore welding is challenging due to harsh environmental conditions, including saltwater corrosion, high winds, and limited accessibility to welding sites. Robotic systems mitigate these challenges by providing precision and adaptability.

Q: What is the impact of robotic welding on job opportunities in the marine industry?

A: While robotic welding reduces the need for manual welding, it creates opportunities in programming, operating, and maintaining robotic systems, requiring a shift in workforce skills.

Q: How do robotic welding systems handle underwater applications?

A: Specialized robotic systems designed for underwater welding use advanced sealing and insulation to operate in submerged conditions, maintaining high weld quality even in extreme depths.

Robotic welding is revolutionizing offshore platform construction by delivering precision, efficiency, and safety. From reduced labor costs to improved project timelines, its benefits are undeniable. As marine industries continue to embrace automation, the market outlook for robotic solutions remains promising, setting the stage for a future where offshore construction is more sustainable and efficient.

Investing in robotic welding systems not only enhances operational capabilities but also positions companies at the forefront of innovation in the ever-evolving marine construction industry.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.