Posted on Friday, November 15, 2024

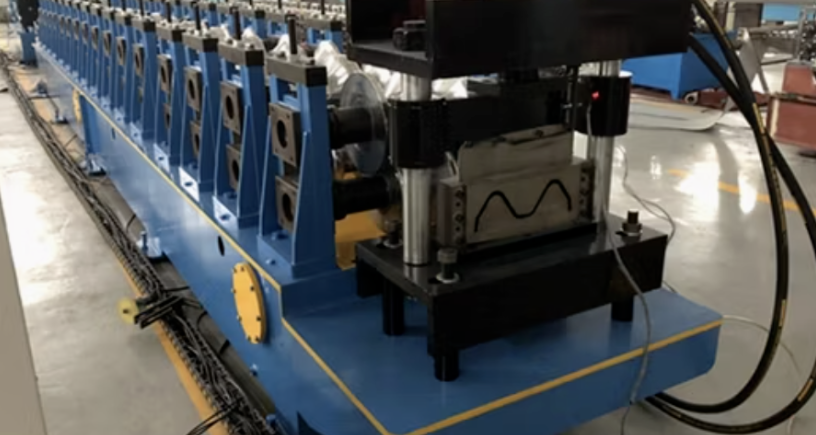

Roll forming machines are indispensable for industries producing metal profiles and components. Greece, with its unique industrial landscape, presents specific considerations for buyers of roll forming machines. This guide provides detailed insights into buying new and used roll forming machines, focusing on critical factors like profiles, power supply, shipping, and compliance.

Q1: What types of profiles are most common in Greece, and how do I ensure my machine supports them?

A1: Roofing panels, decking, and agricultural profiles are prevalent in Greece. Before purchasing, consult your supplier with the specific profile dimensions and material gauge requirements.

Q2: What power supply considerations should I have when buying a roll forming machine in Greece?

A2: Greece typically uses 230V single-phase and 400V three-phase power supplies. Confirm that your machine matches these specifications or arrange for a compatible transformer.

Q3: Are used roll forming machines a good option for small businesses in Greece?

A3: Yes, used machines can be cost-effective for smaller operations. Ensure they are well-maintained and suitable for your production needs.

Q4: How can I verify the quality of a used roll forming machine?

A4: Inspect the machine personally or hire an expert. Review maintenance logs, check for wear on critical components, and test the machine if possible.

Q5: What are the shipping and installation challenges for roll forming machines in Greece?

A5: Shipping costs can vary based on the machine's size and origin. Installation should be handled by experienced technicians to ensure proper setup and compliance with safety regulations.

Q6: Should I prioritize local or international suppliers?

A6: Local suppliers may offer better after-sales support and quicker service. However, international suppliers might provide more options and competitive pricing. Balance both factors based on your requirements.

This guide serves as a starting point for businesses in Greece to make informed decisions when investing in roll forming machines. By carefully evaluating new and used options and considering local factors like profiles, power supply, and shipping, you can ensure a successful purchase.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.