Posted on Tuesday, November 19, 2024

Panama's economy is diverse, with significant growth in key sectors like construction, automotive, and agriculture. Roll forming technology has become a critical part of these industries, driving efficiency, precision, and scalability.

Panama’s construction sector is booming, thanks to ongoing infrastructure projects, residential developments, and commercial expansions. Roll forming machines play a vital role in producing high-quality components for various construction needs.

Applications of Roll Forming in Construction:

Key Benefits for the Construction Sector:

Though Panama doesn’t have a significant automobile manufacturing base, the automotive industry benefits from roll forming in the production of components for vehicle assembly and maintenance.

Applications of Roll Forming in Automotive:

Key Benefits for the Automotive Sector:

Agriculture remains a critical sector in Panama, providing employment and sustaining rural economies. Roll forming machines support the agriculture industry by manufacturing equipment and infrastructure components.

Applications of Roll Forming in Agriculture:

Key Benefits for the Agriculture Sector:

Panama’s strategic location and growing industrial sectors present significant opportunities for expanding roll forming technology. The Panama Canal Expansion Project and ongoing urbanization demand custom profiles for bridges, ports, and urban infrastructure. Similarly, renewable energy projects could use roll-formed profiles for solar panel mounting systems and wind turbine components.

Roll forming technology is a cornerstone of industrial growth in Panama. Its applications in construction, automotive, and agriculture demonstrate its versatility and importance in meeting the needs of a dynamic economy. By adopting advanced roll forming machines, industries in Panama can enhance productivity, reduce costs, and meet global standards.

Are you part of an industry looking to adopt roll forming technology? Explore tailored solutions to meet your specific needs with Machine Matcher, your trusted partner in roll forming machines.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

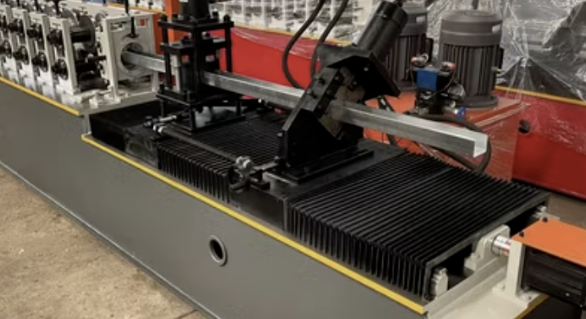

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.