Posted on Wednesday, December 18, 2024

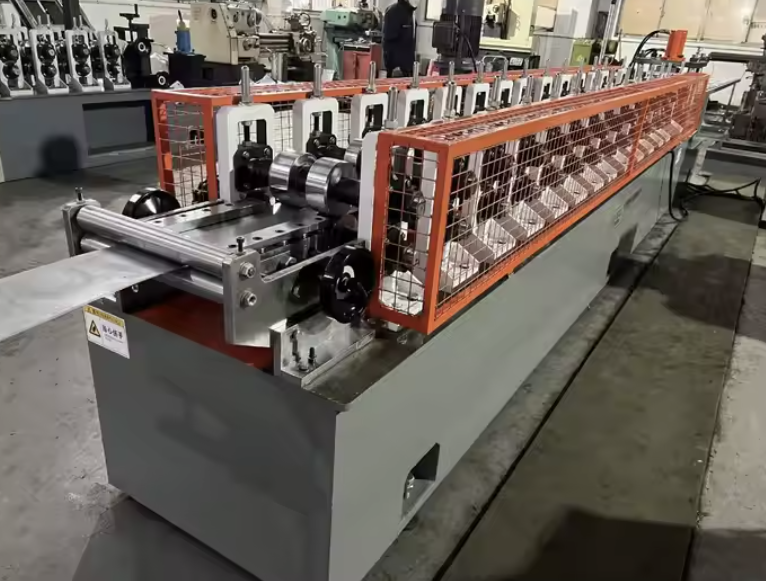

Algeria’s growing construction, infrastructure, and industrial sectors have seen a surge in demand for reliable and high-performing roll forming machines. Whether you’re manufacturing roofing sheets, wall cladding, steel framing, or custom trims, choosing the right roll forming machine is crucial to success.

In this blog, we’ll explore the most popular roll forming machines in Algeria, their specifications, the profiles they produce, the industries that use them, and how Machine Matcher can help you find the perfect machine for your business.

Profiles Produced: Trapezoidal, Corrugated, IBR

Material Thickness: 0.3 – 0.8 mm galvanized steel or pre-painted coils

Rollers: 18–22 stations, chrome-coated steel (GCr15)

Speed: 10–15 m/min (standard), up to 40 m/min (high-speed)

Industries: Construction, Roofing Contractors, Metal Building Fabricators

Profile Range: C & Z profiles from 80–300 mm width

Material Thickness: 1.2 – 3.0 mm galvanized or black steel

Changeover: Manual, semi-auto or fully automatic profile adjustment

Speed: 10–20 m/min

Industries: Structural Framing, Warehouses, Industrial Buildings

Profiles: Metal decking for concrete floors

Material: 0.8 – 1.5 mm galvanized steel

Features: Embossing rollers, high rib designs, hydraulic cutting

Industries: Multi-story Construction, Commercial & Public Buildings

Profiles: U and C studs/tracks for drywall partitions

Material Thickness: 0.4 – 0.8 mm

Speed: 30–40 m/min (high-speed options available)

Industries: Interior Partition Systems, Drywall Contractors

Profiles: Half-round, box, or K-style gutters

Material: 0.5 – 0.7 mm aluminum, steel, or copper

Industries: Residential and Commercial Roofing Systems

Construction and Real Estate Development

Steel and Building Product Manufacturers

Public Infrastructure Contractors

Export-Focused Metal Fabricators

Renewable Energy and Agricultural Structures

Daily: Lubricate moving parts, check for loose bolts

Weekly: Clean rollers and guides, inspect hydraulic oil level

Monthly: Inspect electrical components, PLC systems, and chain drives

Annually: Replace worn-out rollers, re-align shafts, update software (if applicable)

Preventive maintenance ensures smooth operation, extends machine life, and minimizes downtime.

Q1: Can I use one roll forming machine for multiple profiles?

A: Some machines offer interchangeable tooling or automatic width adjustment—ideal for multiple profiles. Others are fixed and designed for specific applications.

Q2: How long does it take to set up a roll forming machine in Algeria?

A: Setup usually takes 1–2 days with skilled technicians and proper foundations. Commissioning and training may take an additional 1–2 days.

Q3: What is the power supply standard in Algeria for these machines?

A: Most machines in Algeria operate on 380V, 50Hz, 3-phase power.

Q4: Can Machine Matcher help with installation and after-sales support?

A: Yes. We can connect you with experienced engineers for installation, training, and long-term support.

Low-End Machines (Used or Manual Models): $10,000 – $25,000

Mid-Range (Standard PLC-controlled, semi-auto): $25,000 – $60,000

High-End (Fully automatic, fast-speed, complex profiles): $60,000 – $120,000+

Prices depend on profile complexity, speed, number of rollers, hydraulic systems, and automation level.

Steps for setup:

Concrete foundation and space allocation

Power connection and grounding

Coil loading and alignment

Calibration for profile

PLC program loading

Trial production run and quality check

Operation includes:

Loading coil on uncoiler

Feeding material through rollers

Monitoring PLC screen

Adjusting cutting length and profile control

Stacking and packaging finished products

While many Algerian companies import roll forming machines, local and regional suppliers include:

Eurl Lamine Profil

Almetech Algeria

Sarl Metal Profil

Imported Machines from Turkey, Italy, and China are also popular for roofing and structural profiles.

At Machine Matcher, we specialize in connecting you with the best roll forming machines suited to your exact profile needs and industry applications.

✅ New and Used Machines

✅ Profile Customization Assistance

✅ Coil Supply & Profile Sketch Matching

✅ Shipping and Setup Support

✅ Local Power & Voltage Adjustments

✅ After-Sales Service & Spare Parts

We match the right machine to your business, your budget, and your market demand.

Let’s help you choose the perfect roll forming machine for your needs in Algeria.

UK: +44 20 335 56554

USA: +1 407 559 7948

Europe: +32 460 24 13 95

WhatsApp: +44 20 335 56554

Email: [email protected]

Website: www.machinematcher.com

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.