Posted on Monday, January 27, 2025

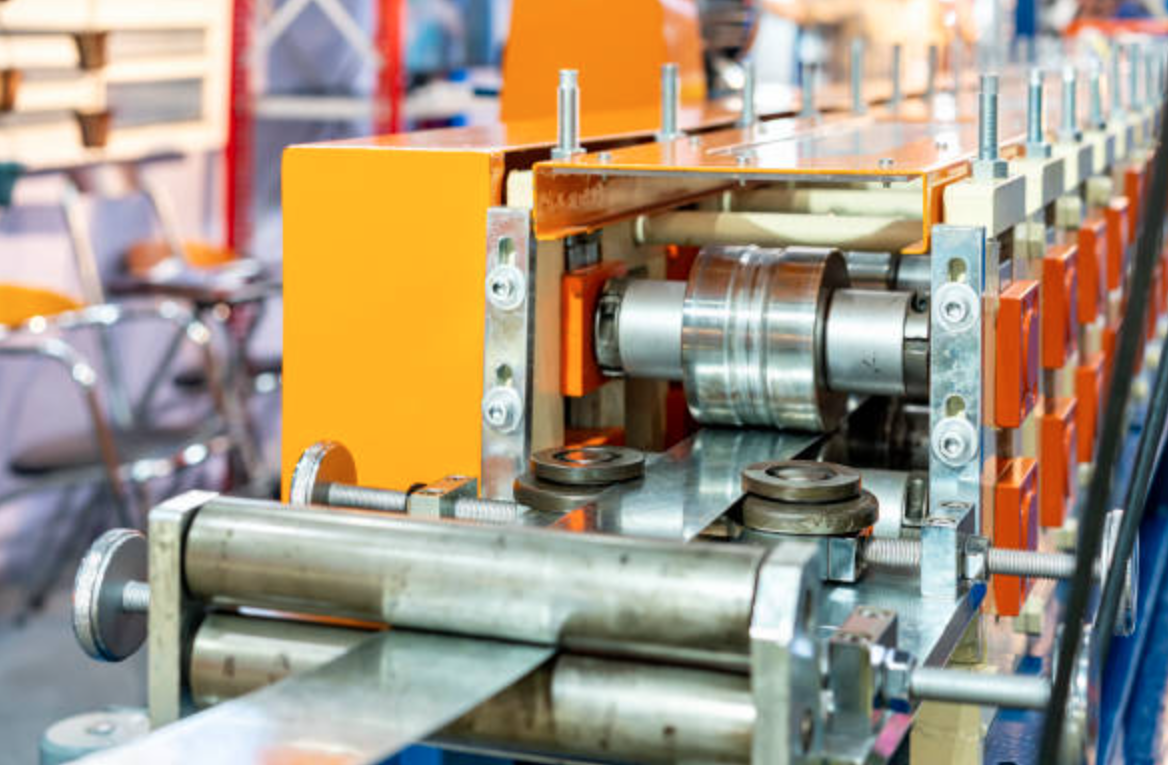

Properly adjusting the entry guides on a roll forming machine is essential to ensure the production of high-quality profiles and reduce material waste. Entry guides align the raw material as it enters the roll forming machine, preventing it from feeding incorrectly, which can lead to defects in the finished product.

Entry guides are critical for maintaining alignment and ensuring that the material feeds smoothly into the forming rollers. Misaligned material can lead to:

Proper adjustment ensures that the material remains centered and parallel as it moves through the machine.

Before making adjustments, perform the following checks:

Follow these steps to adjust the entry guides:

After adjusting the entry guides, perform a test run to verify the setup:

If any issues are detected, repeat the adjustment process until the material feeds smoothly and the profile meets quality standards.

To maintain optimal performance, incorporate these practices into your routine:

Adjusting the entry guides on a roll forming machine is a crucial step to ensure efficient operation and high-quality output. By following the steps outlined in this guide, you can minimize defects, reduce downtime, and extend the life of your machine. Regular maintenance and attention to detail will help you achieve consistent results and maximize productivity.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.