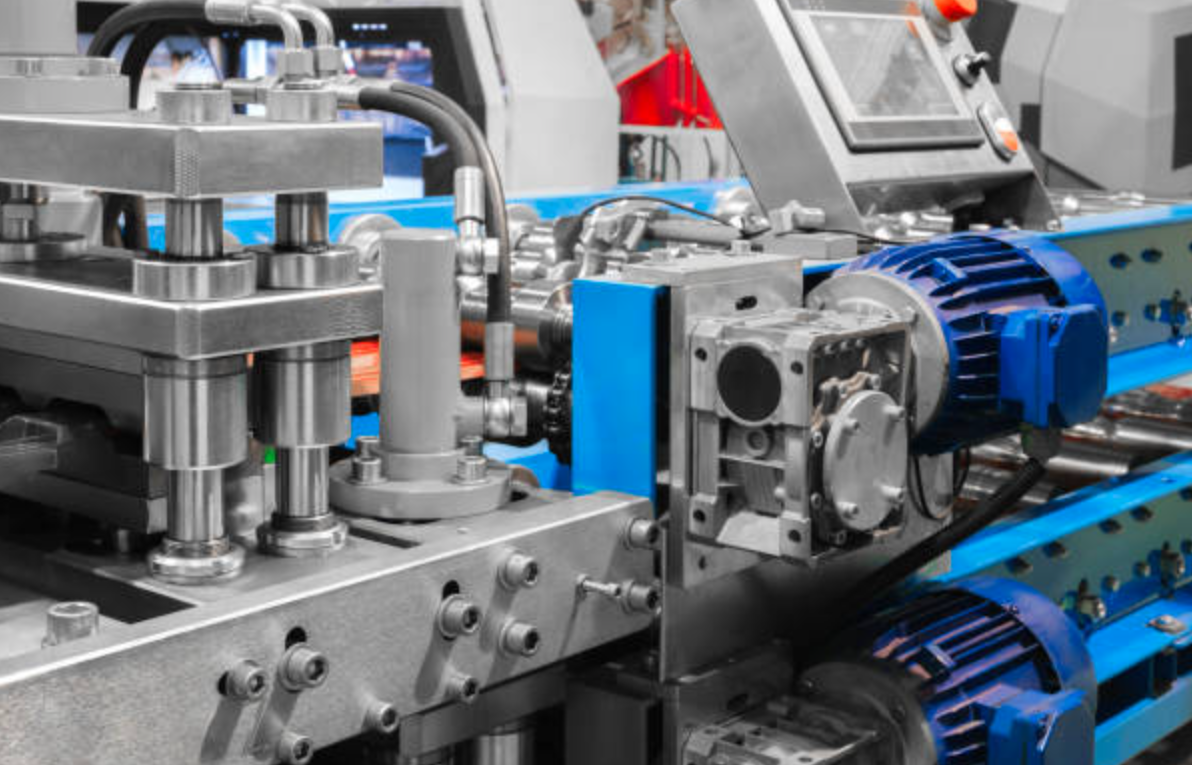

Maintaining motors on a roll forming machine is crucial to ensure the machine operates efficiently and reduces the risk of downtime.

1. Regular Inspection

- Visual Checks: Inspect the motor for visible damage, corrosion, or wear on cables, housing, and connections.

- Listen for Unusual Sounds: Strange noises may indicate internal wear or damage.

- Check for Vibrations: Excessive vibration could signal misalignment, imbalance, or worn bearings.

2. Clean the Motor

- Remove Dust and Debris: Use a dry cloth or compressed air to clean dust and debris from the motor surface and ventilation openings.

- Prevent Moisture Accumulation: Ensure the motor is kept dry, especially in humid environments.

3. Lubricate Moving Parts

- Bearings: Lubricate the motor bearings at regular intervals based on the manufacturer’s recommendations.

- Use Correct Lubricants: Always use the recommended type of grease or oil to prevent compatibility issues.

4. Monitor Electrical Connections

- Check Wiring: Inspect the motor’s wiring for loose or damaged connections.

- Measure Voltage and Current: Use a multimeter to check if the motor is receiving the correct voltage and operating within its current limits.

5. Inspect the Cooling System

- Ventilation: Ensure vents are clear of obstructions for proper airflow.

- Cooling Fans: Check that cooling fans are functioning and free of debris.

6. Monitor Motor Performance

- Temperature: Use an infrared thermometer to ensure the motor is not overheating.

- Speed and Torque: Verify the motor is delivering the required speed and torque for the roll forming process.

7. Perform Preventive Maintenance

- Scheduled Downtime: Plan regular maintenance checks to minimize production interruptions.

- Log Maintenance Activities: Keep detailed records of maintenance tasks and motor performance.

8. Replace Worn Components

- Bearings and Seals: Replace worn or damaged bearings and seals promptly to avoid further damage.

- Brushes (for DC Motors): Check and replace brushes in DC motors as needed.

9. Align and Balance the Motor

- Shaft Alignment: Ensure the motor shaft is properly aligned with the connected equipment.

- Balance Rotating Parts: Misaligned or unbalanced components can cause motor stress and damage.

10. Follow Manufacturer Guidelines

- Consult the Manual: Refer to the motor manufacturer’s maintenance guidelines for specific instructions.

- Service Schedule: Adhere to the recommended service intervals and parts replacement schedules.

11. Emergency Readiness

- Spare Parts: Keep essential spare parts like bearings, seals, and capacitors in stock.

- Contact Professionals: Have a reliable service provider for advanced motor repair or troubleshooting.

By following these maintenance steps, you can maximize the lifespan of your roll forming machine's motors and ensure uninterrupted operation. Regular care and attention will also help reduce repair costs and prevent production delays.