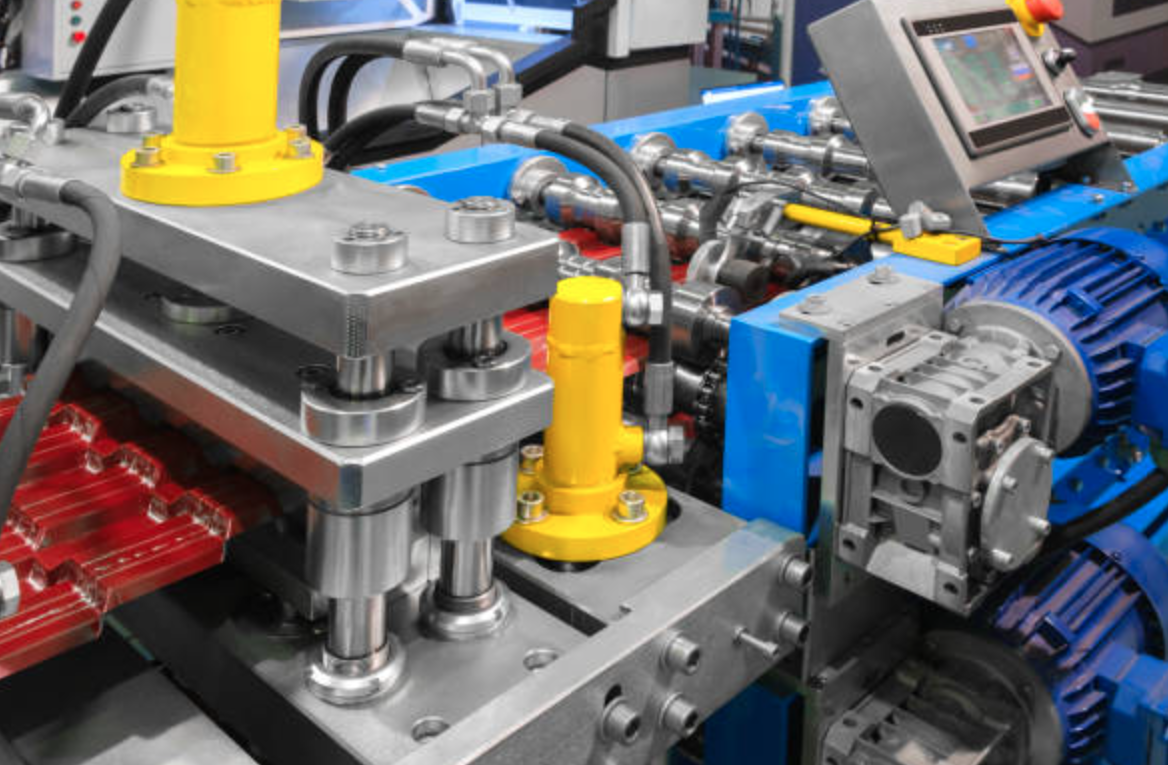

In the fast-paced world of manufacturing, staying competitive requires constant improvements. Upgrading the control panels of your roll forming machines is one of the most effective ways to enhance productivity, ensure precision, and future-proof your operations.

Why Upgrade the Control Panel?

Control panels are the nerve centers of roll forming machines. An upgrade can bring numerous advantages:

- Enhanced Precision and Efficiency

Modern control panels with advanced PLC (Programmable Logic Controller) systems improve operational accuracy, reducing material waste and errors. - Integration with Automation

Upgraded panels can integrate seamlessly with automated systems like remote monitoring, robotic handling, and advanced sensors, streamlining production processes. - Improved Safety

New control panels come with enhanced safety features, such as emergency stop mechanisms, better diagnostics, and compliance with modern safety standards. - Better Data Management

Advanced control systems provide real-time data on performance, material usage, and machine health, empowering data-driven decision-making. - Support for Advanced Profiles

With upgraded controls, machines can handle complex profiles and material variations, opening new business opportunities.

Key Features of Modern Control Panels

When upgrading, look for the following features:

- PLC and HMI Integration

Ensure the panel includes a modern PLC and an intuitive Human-Machine Interface (HMI) for easier operation and programming. - Remote Monitoring Capabilities

Support for remote diagnostics and operation through IoT-enabled systems. - Compatibility with Existing Systems

The control panel should integrate seamlessly with your current roll forming machine and production line. - Advanced Safety Systems

Include safety relays, emergency stops, and fault detection mechanisms. - User-Friendly Design

The interface should be easy to navigate, with multilingual support if required.

Steps to Upgrade the Control Panel

- Assess the Current System

Evaluate your existing control panel to identify limitations and define upgrade objectives. - Determine Requirements

Decide on the features needed for your production goals, such as automation, safety, or compatibility with specific profiles. - Consult a Professional

Partner with a trusted vendor or engineer specializing in roll forming machines to design the upgrade. - Select the Right Components

Invest in high-quality PLCs, HMIs, relays, sensors, and wiring. - Installation and Testing

Have the new control panel installed by professionals. Conduct thorough testing to ensure the system works flawlessly. - Training for Operators

Provide training for your team to ensure they are familiar with the new control panel’s features and functions.

Cost Considerations

Upgrading a control panel can range from a few thousand dollars for basic enhancements to more for fully integrated systems. Factors influencing the cost include:

- The complexity of the machine

- Required features and technology

- Installation and labor costs

- Downtime during the upgrade

Benefits of Upgraded Panels in Real-World Scenarios

Case Study: Enhanced Efficiency in Roof Panel Production

A roofing manufacturer upgraded their roll forming machine's control panel to include advanced PLCs and IoT monitoring. The upgrade resulted in:

- 30% reduction in production downtime

- Improved material utilization by 20%

- Ability to manufacture custom profiles efficiently

Maintenance and Support Post-Upgrade

Once your control panel is upgraded, regular maintenance is crucial:

- Scheduled Maintenance

Check and update software and firmware periodically. - Diagnostics and Monitoring

Use the panel’s diagnostic tools to preemptively address issues. - Vendor Support

Choose a vendor that provides ongoing support and training.

Conclusion

Upgrading the control panel on your roll forming machine is a strategic investment that can enhance productivity, reduce waste, and future-proof your operations. With the right planning, components, and support, this upgrade can transform your manufacturing process and keep you ahead in the competitive market.

Are you considering upgrading your roll forming machine's control panel? Contact us for expert advice and solutions tailored to your needs!