Posted on Friday, May 23, 2025

A drip edge is a metal flashing installed at the edges of a roof to direct water away from the fascia and underlying roofing components. It helps protect the building from water damage, rot, and pest intrusion by ensuring that runoff flows into the gutters and away from the structure.

Drip edges are a standard in both residential and commercial roofing systems and are often required by building codes in North America and other regions due to their role in prolonging roof life.

Moisture Protection: Prevents water infiltration under shingles or roofing panels.

Fascia Protection: Shields wooden fascia boards from water staining and rot.

Gutter Efficiency: Ensures water flows directly into the gutter system.

Aesthetic Finish: Offers a clean, finished look to the roofline.

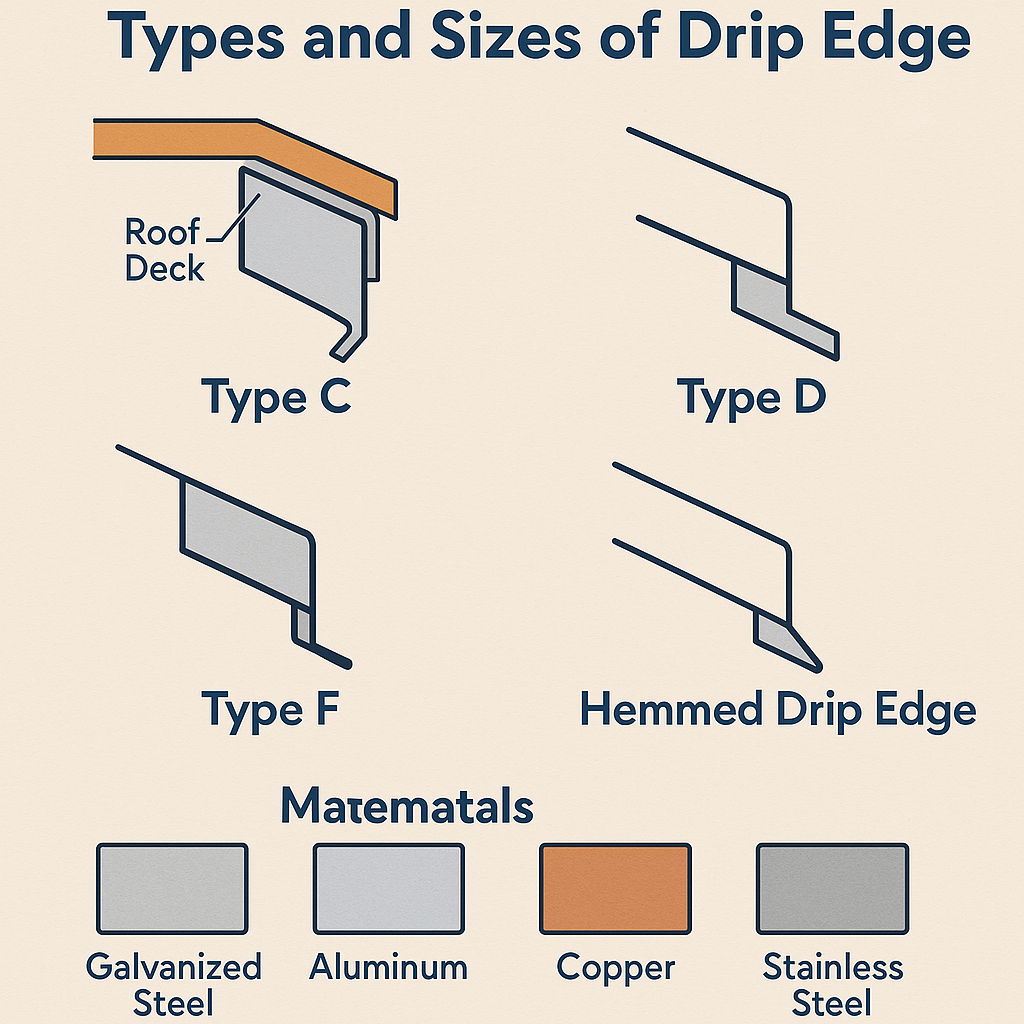

Drip edge profiles vary based on regional preferences, building codes, and roofing materials. The most common types include:

Resembles a 90-degree angle.

Common in older homes.

Simple to install.

Features a flange that kicks water away from the fascia.

Offers better water redirection than Type C.

Most popular for modern roofing systems.

Extends further back on the roof deck.

Ideal for reroofing and drip edge replacement.

Rolled edge for added safety and strength.

Often used in commercial metal roofing.

Designed for specific architectural or industrial applications.

Often made using roll forming machines tailored to unique sizes.

Different environments and roof types require specific materials. Common materials include:

| Material | Benefits | Typical Uses |

|---|---|---|

| Galvanized Steel | Durable, rust-resistant (if coated) | Residential, commercial buildings |

| Aluminum | Lightweight, corrosion-resistant | Coastal homes, metal roofs |

| Copper | Elegant, durable, naturally patinas | High-end residential, historic renovations |

| Stainless Steel | Corrosion-proof, high tensile strength | Industrial, chemical, coastal applications |

| Painted Steel | Aesthetic and rust protection | Residential roofing with colored panels |

Typical drip edge dimensions:

Vertical leg (fascia drop): 1" to 4"

Roof flange (under-shingle): 2" to 5"

Drip kick-out lip: ¼" to ½"

Material thickness (gauge):

Aluminum: 0.019" to 0.032"

Steel: 24 to 30 gauge

Copper: 16 to 20 oz

Larger and custom sizes are available through manufacturers or on-site fabrication.

Drip edges aren’t just for residential homes. They're used in:

Residential construction

Commercial buildings

Modular and prefab housing

Warehouses and industrial roofs

Agricultural buildings

Container conversions

Solar panel sheds and outbuildings

Roofing nails or screws

Roofing cement or sealant (if required)

Tin snips

Hammer or drill

Chalk line

Measuring tape

Install underlayment: Place roofing underlayment across the roof deck.

Install eaves drip edge: Start at the eaves. Place the drip edge with the flange extending away from the fascia. Nail every 8–10 inches.

Install side rake edge: Overlap the rake edge over the eave drip edge. This ensures proper water runoff.

Seal overlaps: Where sections meet, overlap by 1–2 inches. Seal joints if in a high wind or ice-prone area.

Add shingles or roofing panels: Install roofing over the drip edge flange for best protection.

When selecting a drip edge, consider:

Climate: Use aluminum or stainless steel in coastal zones.

Roof type: Type D or F for steep-slope or metal roofs.

Color and aesthetics: Painted or copper drip edges for visible applications.

Building codes: Always check local requirements (e.g., IRC in the U.S.).

Here are notable U.S.-based manufacturers:

ABC Supply Co., Inc.

Amerimax Building Products

Petersen Aluminum (PAC-CLAD)

Fabral

MBCI (Metal Building Components Inc.)

Englert Inc.

Rollex

Metal Sales Manufacturing Corporation

Westlake Royal Building Products

TAMKO Building Products

CertainTeed

Gibraltar Industries

Mid-America Siding Components

Union Corrugating

Berger Building Products

Berridge Manufacturing Company

Firestone Building Products (now part of Holcim)

ATAS International

Georgia-Pacific Building Products

Mule-Hide Products Co., Inc.

Kingspan Group (Ireland)

ArcelorMittal Construction (Global)

Ruukki (Finland)

Tata BlueScope Steel (India/Australia)

Metecno Group (Italy/Global)

Blachotrapez (Poland)

Lindab (Sweden)

Swisspearl Group (Switzerland)

Isopan (Italy)

Dongkuk Steel (South Korea)

CSM Metal Deck (Thailand)

Zamil Steel (Saudi Arabia)

JSW Steel (India)

Shandong Goldensun Steel (China)

Dongbu Steel (South Korea)

Xiamen Liming Machinery Co., Ltd. (China)

SAF – Southern Aluminum Finishing (USA/Global)

VMZinc (France)

Marcegaglia (Italy)

Jindal Steel & Power (India)

Modern roll forming machines produce precision drip edges at high speed using:

GCr15 hardened rollers

Servo-feeding and punching units

Automated shearing and stacking systems

Machine Matcher offers customized drip edge roll forming machines tailored to your profile needs—designed for aluminum, steel, copper, and painted coils.

A: Yes. It prevents water damage, extends the life of your roof, and is often required by building codes.

A: Yes, but it’s more challenging. A Type F (gutter apron) is recommended for retrofits.

A: Aluminum or stainless steel due to their corrosion resistance.

A: Yes. Many drip edges come pre-painted to match the roof or trim.

Whether you're a contractor, architect, or metal fabricator, choosing the right drip edge is critical for roof integrity. Machine Matcher connects you with drip edge roll forming machines and global suppliers to match your material, profile, and production needs.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.