Posted on Friday, May 23, 2025

Metal embossing is an essential process in metalworking that involves creating raised or recessed designs on metal sheets. These embossed patterns serve both functional and decorative purposes in various industries ranging from architecture and automotive to consumer products.

In this guide, we’ll cover:

What embossed metal is

How the embossing process works

Common materials used

Profile types and sizes

Applications by industry

Top manufacturers in the USA

Top 20 global manufacturers

FAQs about metal embossing

Embossed metal refers to metal sheets that have been pressed or stamped to create raised or indented designs. The process improves both visual aesthetics and mechanical properties such as grip, rigidity, and ventilation.

Common purposes:

Aesthetic enhancement

Improved friction or grip

Structural stiffness

Branding/logos

Anti-slip surfaces

Metal embossing is typically performed using matched male and female roller dies or a punch and die system.

Two main methods:

Roller Embossing: Ideal for continuous patterns on sheet or coil material.

Stamping/Die Embossing: Better for individual parts or specific shapes.

Material preparation – Coil or sheet is cleaned and cut.

Embossing – Material is fed through embossing rollers or a press with dies.

Finishing – Post-processing like anodizing, painting, or polishing may follow.

Different industries require different materials depending on strength, formability, and finish.

| Material | Advantages | Common Applications |

|---|---|---|

| Aluminum | Lightweight, corrosion-resistant | HVAC, ceiling tiles, decorative panels |

| Stainless Steel | Strong, durable, corrosion-resistant | Elevators, wall panels, food processing |

| Galvanized Steel | Rust-resistant, cost-effective | Industrial flooring, wall cladding |

| Copper | Malleable, antimicrobial, aesthetic | Roofing, backsplashes, art |

| Brass | Decorative, high-end appearance | Furniture, signage, architectural use |

| Cold-Rolled Steel | Smooth finish, structural use | Security panels, automotive parts |

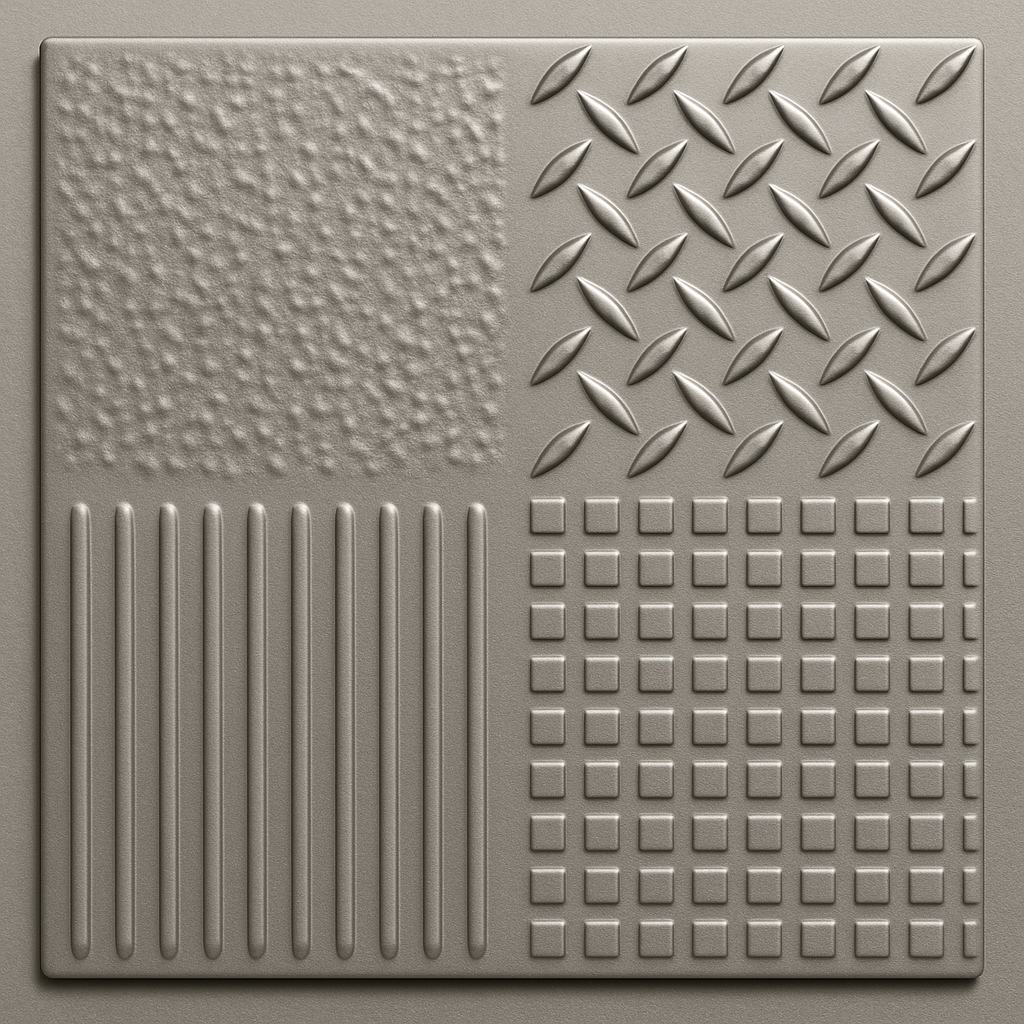

Metal embossing offers a wide variety of textures and designs, tailored for both function and style.

Stucco

Woodgrain

Leather grain

Sand finish

Diamond

Checker plate

Linear ribbed

Crosshatch

Logos

Decorative scrolls

Artwork reproduction

| Thickness Range | 0.3 mm – 2.5 mm (varies by material) |

|---|---|

| Width Range | 600 mm – 1500 mm |

| Length Range | 1000 mm – 6000 mm or coil-fed |

Note: Custom die embossing allows for tailored dimensions and profile depths.

Wall cladding

Ceiling tiles

Column wraps

Elevator interiors

Floor panels

Interior trim

Anti-slip surfaces

Kitchen equipment

Ventilation panels

Sanitary wall coverings

Decorative panels

Furniture accents

Packaging

Insulation jacketing

Duct coverings

Machinery guards

RotoMetrics (an MPS company) – Specializes in rotary embossing tooling.

MCI (Metalcraft Industries Inc.) – Offers embossing, stamping, and custom sheet processing.

McNichols Company – Leading supplier of textured and embossed metal products.

Impressart – Focuses on small-scale and artistic metal embossing.

H&H Metals – Embossing services for architectural and construction uses.

Rolled Alloys – Provides textured stainless and nickel alloy sheets.

Ashland Aluminum – Precision aluminum embossing.

United Aluminum – Coil processing and embossing.

Tex Metals – Metal textures for industrial and architectural uses.

Advanced Architectural Metals – Custom panels and decorative sheet embossing.

Alubond (UAE/USA)

Metalsistem (Italy)

Interflex (South Africa)

Yieh Corp. (Taiwan)

Assan Aluminyum (Turkey)

Haomei Aluminum (China)

Shanghai Metal Corporation (China)

Jindal Stainless (India)

Outokumpu (Finland)

POSCO (South Korea)

Aleris Rolled Products (USA/Global)

Norsk Hydro (Norway)

Arconic (USA)

Thyssenkrupp Materials (Germany)

BlueScope Steel (Australia)

GARMCO (Bahrain)

Imcar (Italy – embossing machines)

Dimeco (France – coil processing & embossing)

Bradbury Group (USA – embossing & forming lines)

Jinan Huaxia (China – embossing lines)

Yes, small-scale embossing kits allow artists and DIY users to emboss soft metals like aluminum and copper using hand tools or mini presses.

Embossing raises the metal surface.

Debossing depresses it inward.

No. It also enhances grip, strength, and thermal transfer. For example, embossed aluminum jacketing improves insulation performance in HVAC systems.

Embossing can be done with:

Rotary roller machines

Hydraulic presses

CNC embossing machines for custom shapes

Metal embossing combines functionality with aesthetics, making it essential across multiple industries—from decorative interiors to industrial strength applications. Whether you’re sourcing embossed sheets or the machines that produce them, understanding the materials, patterns, and industry trends will help you make the right decisions.

At Machine Matcher, we help connect you with the right machine based on your embossing requirements, material types, and profile needs. Our network includes both U.S. and global suppliers of metal embossing machines and sheet materials. Contact us for expert guidance.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.