Posted on Friday, May 23, 2025

Metal roofing panels are becoming the material of choice for commercial, industrial, agricultural, and even residential buildings. Known for their durability, energy efficiency, and modern appearance, metal roof panels come in a variety of types, sizes, and finishes suited to a wide range of climates and applications.

Metal roof panels are manufactured sheets of steel, aluminum, copper, or zinc designed to protect structures from environmental elements. They are formed by roll forming machines into specific profiles that suit various aesthetic and structural needs.

| Material | Key Features | Ideal Uses |

|---|---|---|

| Galvanized Steel | Zinc-coated steel; corrosion-resistant | Commercial, industrial roofs |

| Galvalume | Aluminum-zinc alloy coating; long lifespan | Coastal & humid regions |

| Aluminum | Lightweight, rust-proof | Residential, coastal buildings |

| Copper | High-end look, patinas over time | Luxury and historical restoration |

| Zinc | Self-healing surface, extremely durable | Architectural projects |

Typical Material Thickness: 22 – 29 gauge (0.3 mm to 0.8 mm)

Yield Strength Range: 40 KSI to 80 KSI depending on the panel type and material

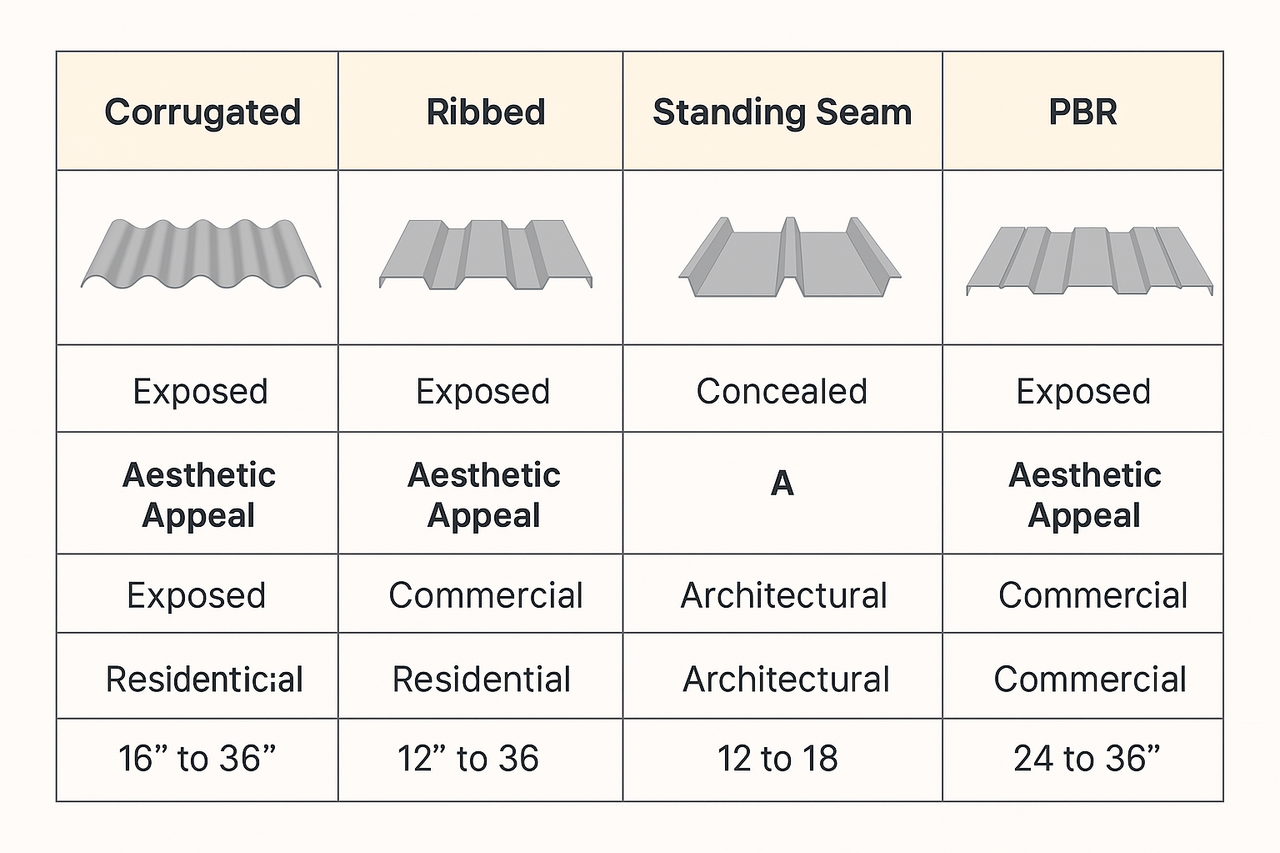

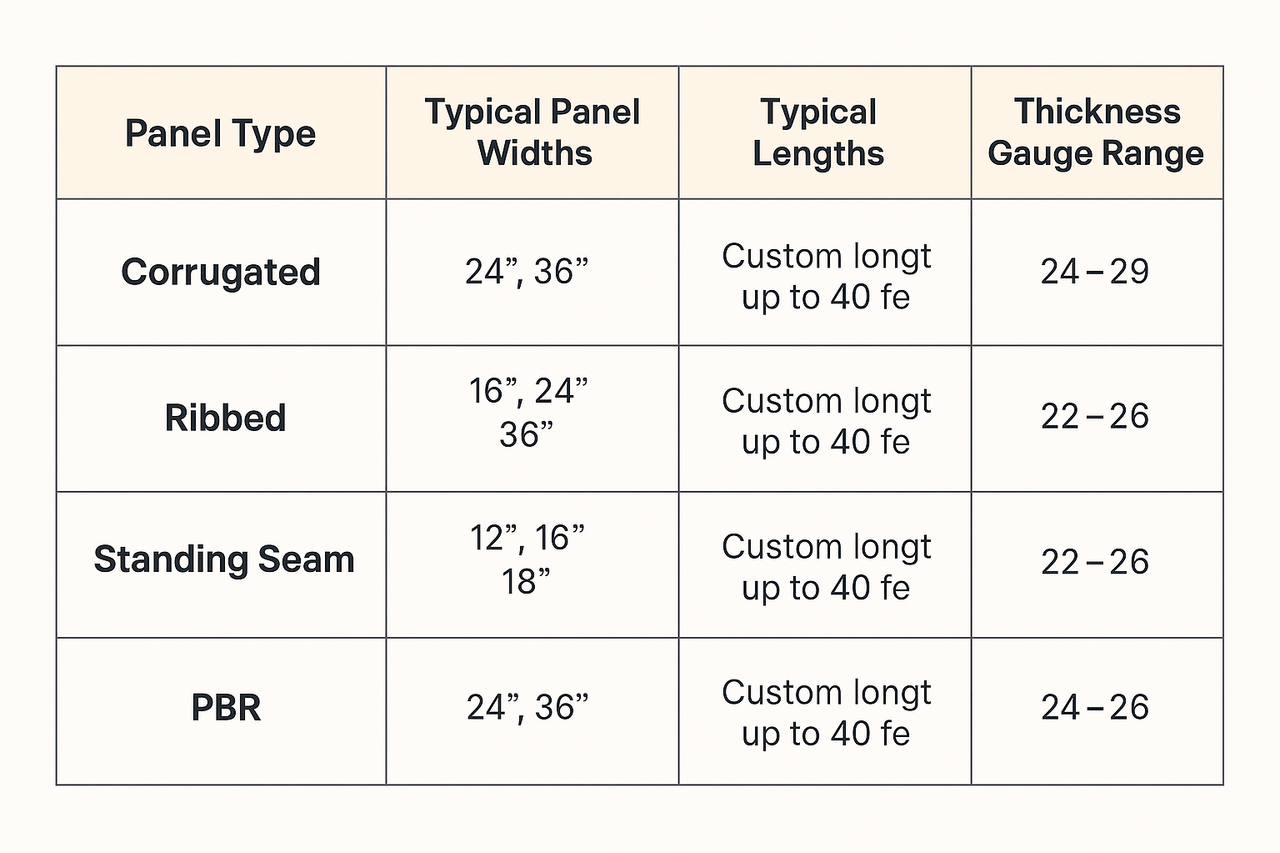

| Profile Name | Description | Common Uses |

|---|---|---|

| Corrugated Panels | Wavy pattern; classic look | Agricultural buildings, sheds |

| Ribbed Panels | Raised ribs for strength | Commercial, barns |

| Standing Seam Panels | Concealed fasteners; modern appearance | Residential, commercial roofs |

| Snap Lock Panels | Interlocking seams for easy installation | Homes and mid-size buildings |

| PBR (Purlin Bearing Rib) | Extra support at lap for better installation on purlins | Steel structures, warehouses |

| R-Panel | Popular low-slope commercial roofing | Warehouses, steel buildings |

| 5V Crimp | Classic look with minimal overlap | Homes, barns, smaller roofs |

Standard Widths: 12", 16", 18", 24", 36"

Length: Custom cut to size, usually up to 40 feet

Rib Height: Ranges from 3/4" to 1.5"

Overlap: 1" to 2" depending on profile

Coverage Width: Varies per profile and panel design

Residential: Modern and energy-efficient housing

Commercial: Retail stores, office buildings, malls

Industrial: Warehouses, factories, logistics hubs

Agricultural: Barns, silos, animal shelters

Public/Government: Schools, hospitals, military buildings

Energy & Utility: Solar panel mounting structures

Hospitality: Resorts, eco-lodges, and off-grid housing

Lifespan of 40–70 years

Fire and wind resistant

Low maintenance

Highly recyclable

Energy efficiency (especially with coatings or cool roof finishes)

Here are some of the leading manufacturers known for quality and innovation:

McElroy Metal

Metal Sales Manufacturing Corporation

Fabral

MBCI (Metal Building Components Inc.)

American Building Components (ABC)

Englert Inc.

ATAS International

Union Corrugating Company

Central States Manufacturing

Reinke Shakes

Everlast Roofing

Berridge Manufacturing Company

Drexel Metals

Firestone Building Products

Sheffield Metals

Petersen Aluminum Corporation

ASC Building Products

AEP Span

Tamko MetalWorks

Bridger Steel

Tata BlueScope Steel (India/Australia)

ArcelorMittal (Luxembourg)

Kingspan Group (Ireland)

Ruukki / SSAB (Finland/Sweden)

Bluescope Steel (Australia)

NLMK (Russia)

Dongkuk Steel (South Korea)

POSCO (South Korea)

Zamil Steel (Saudi Arabia)

Metecno Group (Italy)

Ternium (Latin America)

JSW Steel (India)

Yieh Phui Enterprise Co. (Taiwan)

Baosteel (China)

Corus Group (UK - now part of Tata Steel)

Nippon Steel (Japan)

JFE Steel Corporation (Japan)

Salzgitter AG (Germany)

Severstal (Russia)

Dongbu Steel (South Korea)

Yes. Standing seam panels are ideal for solar installations as mounting brackets can be clamped to the seams, avoiding roof penetration. They are long-lasting and often outlive solar systems.

Use:

Metal shears for small straight cuts

Nibblers for curves

Circular saws with metal blades for larger, straight cuts

Safety Tip: Always wear gloves, goggles, and hearing protection.

Basic steps:

Prepare roof deck (plywood or OSB)

Apply waterproof underlayment

Align starter strip

Overlap panels and fasten with screws (at ridges, not valleys)

Install ridge caps and flashing

Seal edges with butyl tape or foam closures

For standing seam systems, use clip-fastening methods to allow for thermal movement.

| Type | Installed Cost (USD/sq.ft.) |

|---|---|

| Corrugated Panels | $4 – $6 |

| Standing Seam | $8 – $14 |

| Copper | $15 – $30 |

| Aluminum | $7 – $12 |

Total cost depends on gauge, labor, profile type, and location.

Yes. Use paint systems like:

Kynar 500® (PVDF): Premium, long-lasting

Silicone-modified polyester (SMP): Budget-friendly

Acrylic or polyester paints: Shorter life span

Surface prep, priming, and proper curing are essential.

Metal roof panels are more than just a trend—they're a smart investment across residential, commercial, and industrial sectors. With a wide range of profiles, materials, and finishes, they offer unbeatable longevity, environmental benefits, and modern aesthetics.

Whether you're an architect, contractor, or business owner, understanding the types, specs, installation methods, and suppliers will help you make the best decision for your next roofing project.

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.