Posted on Friday, May 23, 2025

Introduction

Standing seam metal roofs are a premium roofing system characterized by their sleek design, superior durability, and concealed fasteners. Unlike traditional metal panels, standing seam systems feature vertical legs and a flat space between them, creating clean, continuous lines from ridge to eave. With lifespans of up to 70 years and minimal maintenance requirements, they are a top choice for architects, commercial builders, and homeowners alike.

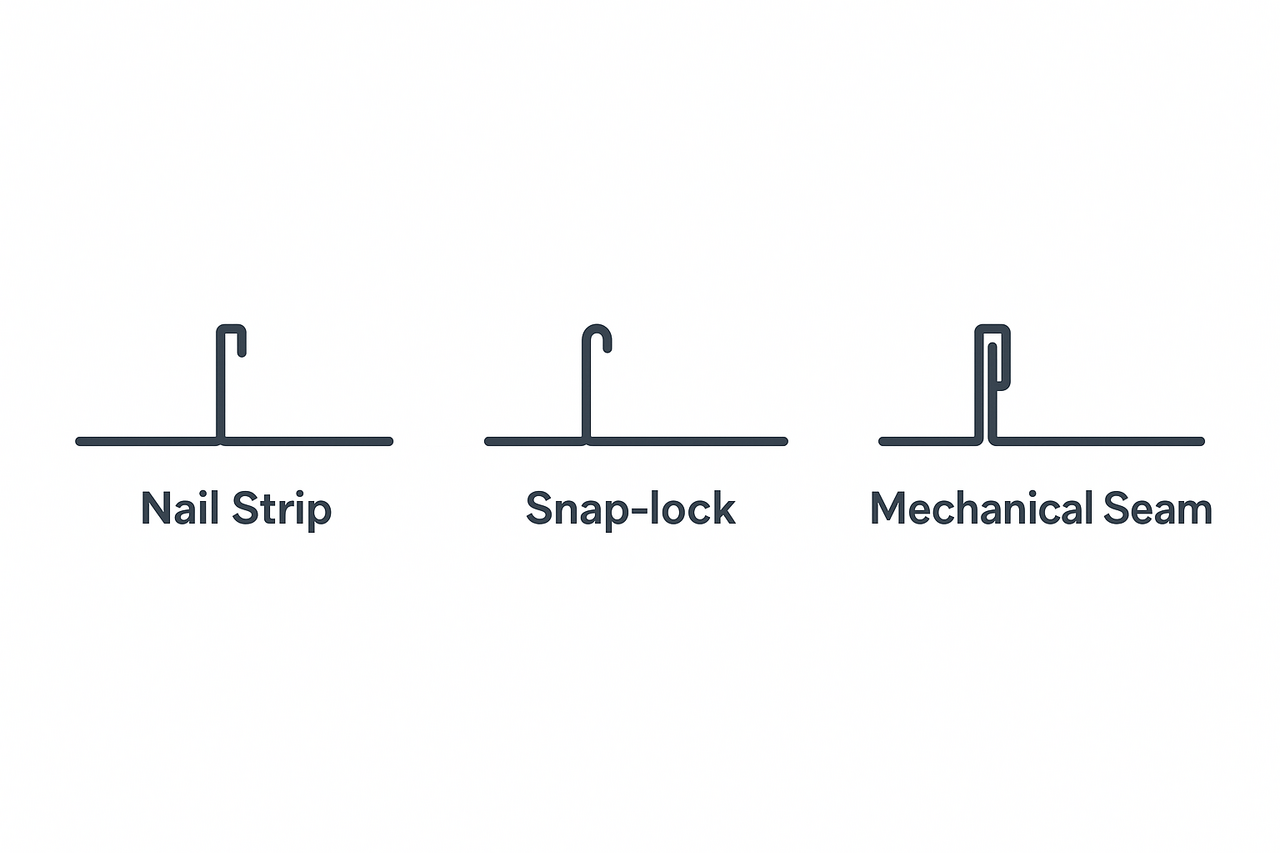

A standing seam roof is defined by its raised interlocking seams that join one metal panel to the next. These raised seams prevent moisture infiltration and allow for thermal expansion and contraction.

Types of Standing Seam Systems:

Seam Heights: Common options include 1", 1.5", 2", and 2.5".

Standing seam systems are suitable for:

Q: Can I install solar panels on a standing seam roof?

A: Yes, clamp-mounted systems work without penetrating panels.

Q: How long do these roofs last?

A: Between 40 and 70 years, depending on material and climate.

Q: What is the average cost per square foot installed?

A: Typically $9–$14 depending on panel type and region.

Q: What panel width is most common?

A: 16" is widely used, but others like 12" and 18" are also available.

Q: What helps prevent oil canning?

A: Use striations, stiffer materials (thicker gauges), and correct fastener spacing.

Standing seam metal roofs offer a blend of style, longevity, and performance that few other systems can match. With a variety of materials, colors, and panel profiles available, they’re suited for nearly every architectural and environmental challenge. Selecting the right panel type and supplier—whether local or international—is key to long-term success.

For standing seam roll forming machines or roof panel machines tailored to your profile and location, contact the Machine Matcher team in the USA or UK.

Contact Info:

Machine Matcher

Phone: +1 (407) 859-1119

Email: [email protected]

Used Purlin Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Purlin & Structural Steel Profiles

Used Roof Panel Roll Forming Machines for Sale Worldwide

Posted on Sunday, January 25, 2026

Pre-Owned Roll Forming Machines for Roofing Panel Production

Used Roll Forming Machines for Sale Worldwide

Posted on Tuesday, January 20, 2026

Pre-Owned Roll Forming Machines with Inspection, Verification & Global Support

Steel Coil Supply for Roll Forming Machines Worldwide

Posted on Tuesday, January 20, 2026

Reliable Steel Coil Supply for Roll Forming, Fabrication & Manufacturing Applications

Copyright 2026 © Machine Matcher.