To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

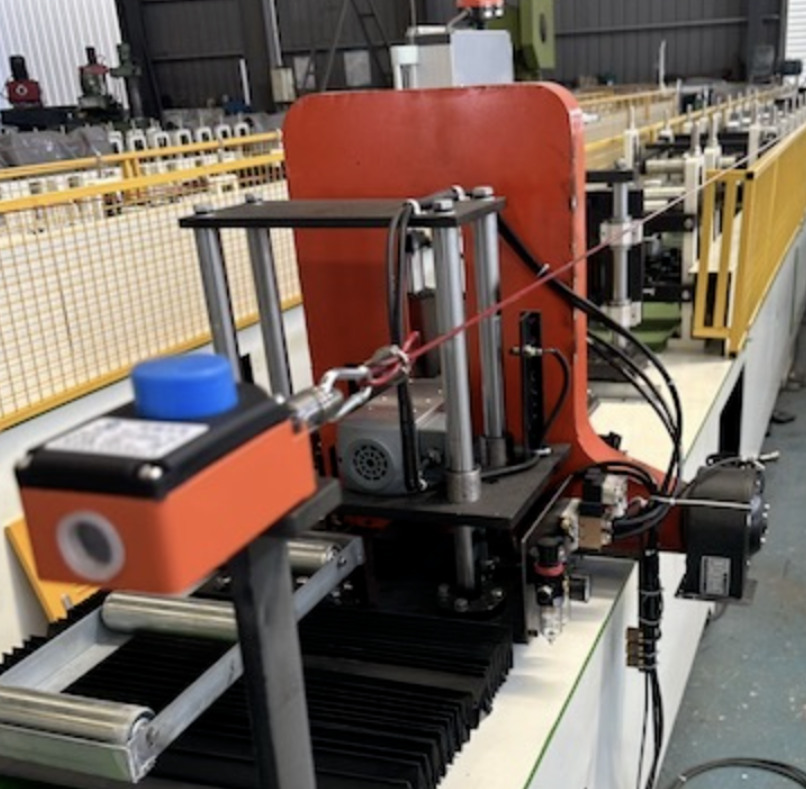

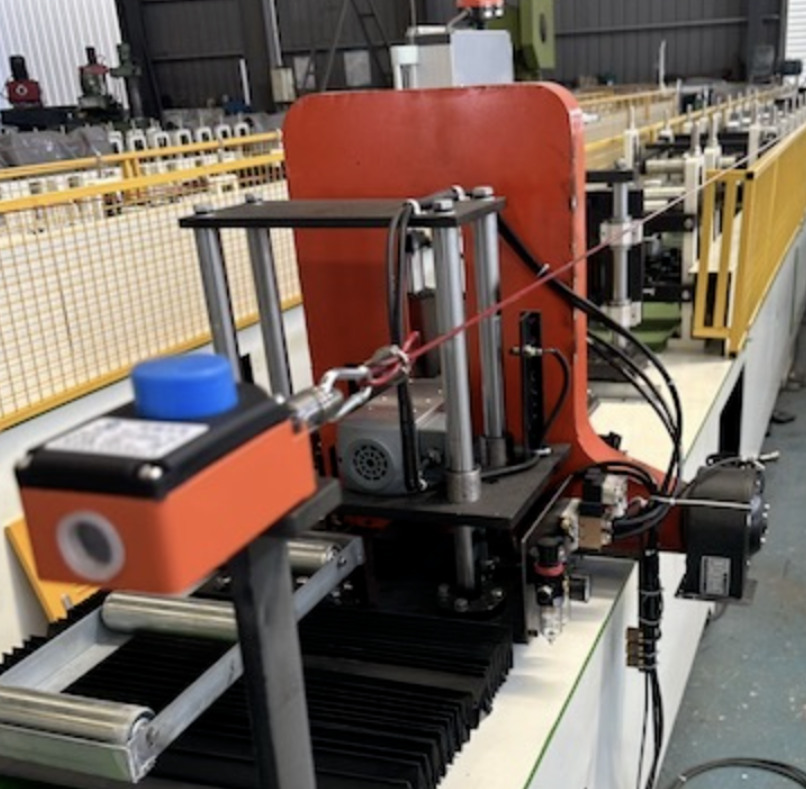

The 2x4 inch tube cold roll forming machine is designed for creating precision 2x4 steel tubes efficiently. These machines are commonly used in the construction, automotive, and manufacturing industries for structural and framing applications. The cold roll forming process ensures smooth finishes, high structural integrity, and dimensional accuracy, making the resulting products ideal for Florida’s construction needs, particularly in hurricane-prone areas where strength and durability are crucial.

This machine can process various materials, including galvanized steel, carbon steel, and stainless steel, to produce rectangular tubes of consistent quality. Its advanced features like automation and precise cutting ensure high productivity and minimal waste.

A: The construction, automotive, furniture, and industrial framing industries are key users. It’s particularly valuable in Florida for hurricane-resistant structures and robust framing.

A: Yes, it can process materials up to 4.0 mm thick. Adjustments can be made for specific applications, ensuring flexibility in production.

A: The machine is designed to operate at 480V/60Hz, which aligns with Florida’s industrial power standards. Customizations are available if needed.

A: The hydraulic cutting system is programmed via the PLC, ensuring cuts are accurate to ±0.5 mm, suitable for high-quality structural applications.

A: Machines can be shipped via freight to major Florida ports such as Miami or Jacksonville. Delivery includes installation and operator training support.

A: Yes, the machine comes with quick-change tooling options, allowing you to produce multiple tube sizes with minimal downtime.

A: Post-purchase support includes a warranty, on-site technician visits, and a dedicated helpline for troubleshooting.

A: Yes, financing options are available for buyers in Florida through local distributors or direct manufacturers.

Copyright 2026 © Machine Matcher.