To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

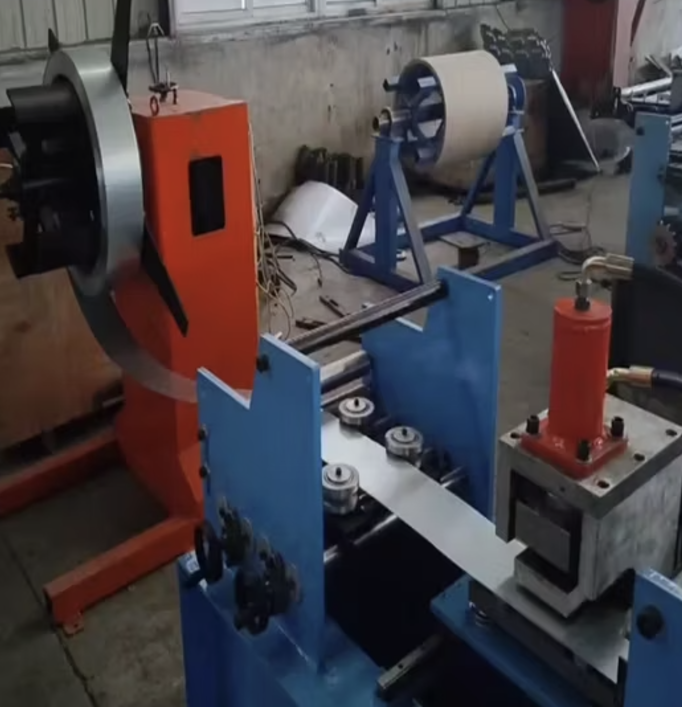

An Angle Steel Roll Forming Machine is a specialized piece of equipment designed for the continuous production of steel angle profiles. These machines are widely used in construction, shelving, and various structural applications. Angle profiles, often referred to as "L-profiles," are known for their strength and versatility, making them ideal for support structures, framing, and brackets.

The machine operates by feeding steel coils through a series of rollers that progressively shape the material into the desired angle profile. With precise engineering, this roll forming machine ensures consistent quality, high efficiency, and minimal material waste.

1. What is the lead time for an Angle Steel Roll Forming Machine in the USA?

Lead times typically range from 8 to 12 weeks, depending on the configuration and customizations required.

2. Can the machine handle thicker steel materials?

Yes, the machine can be customized to handle materials up to 6.0 mm thick with reinforced rollers and motors.

3. What profiles can the machine produce?

The standard profile is an "L" shape, but the machine can be customized to produce angled profiles with variable widths and lengths.

4. Are there financing options available in the USA?

Yes, financing options are available through machine dealers and manufacturers. Many also offer leasing programs.

5. Is there a warranty?

Most manufacturers offer a 12 to 24-month warranty, covering parts and service, excluding consumables like cutting blades.

6. What certifications does the machine meet for the US market?

The machine complies with CE and ISO standards, ensuring safety and quality. Additional certifications (e.g., UL) can be provided upon request.

7. How can I get spare parts?

Spare parts are available through the manufacturer or authorized distributors in the USA. Some suppliers maintain local inventory for faster delivery.

8. What type of support is available after installation?

Manufacturers typically offer online support, on-site servicing, and operator training. Remote PLC diagnostics are also available.

9. Can the machine produce profiles for specific industries?

Yes, the machine can be tailored to produce profiles for specific applications, such as automotive or construction.

10. Is it possible to export profiles to other countries?

Absolutely. Profiles produced by these machines meet international standards, making them suitable for export.

Copyright 2026 © Machine Matcher.