To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

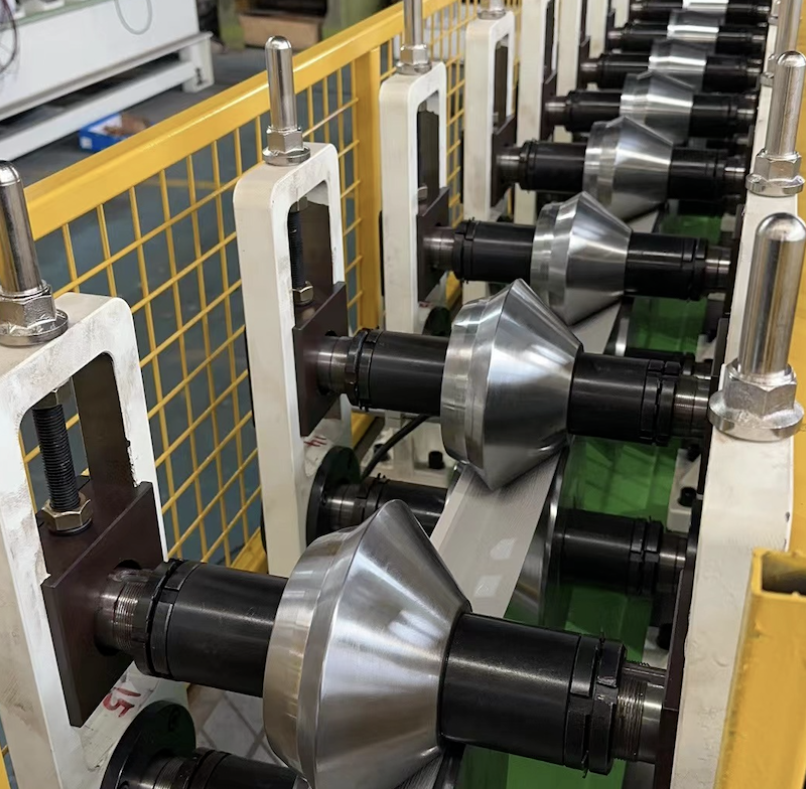

The C5 Drip Edge Roll Forming Machine is a precision-engineered solution designed to produce high-quality C5 drip edge profiles. This cold roll forming machine is ideal for the roofing industry in Florida, USA, where durable and weather-resistant profiles are critical. With an advanced electric-powered system, high production speed, and user-friendly features, this machine ensures efficiency and reliability for manufacturers.

The C5 Drip Edge Roll Forming Machine is built for precision and durability, meeting the specific requirements of Florida’s roofing market. Its compact design and robust frame allow seamless operation, even in high-demand environments.

This machine produces drip edge profiles used in roofing systems to prevent water damage, ensuring a clean finish and enhanced protection against harsh weather conditions. The profiles are formed with minimal material waste, optimizing cost efficiency while maintaining superior product quality.

Q1: What is the primary use of the C5 Drip Edge Roll Forming Machine?

The machine is designed to produce C5 drip edge profiles, which are used in roofing systems to prevent water damage and ensure a clean, professional finish.

Q2: Is the machine suitable for Florida’s power supply?

Yes, the machine operates on a 240V three-phase, 60 Hz power supply, which is standard in Florida.

Q3: What materials can the machine process?

The machine can process galvanized steel, aluminum, and other weather-resistant metals commonly used in roofing applications.

Q4: How fast can the machine produce profiles?

The C5 Drip Edge Roll Forming Machine operates at a speed of 80 feet per minute, making it ideal for high-volume production.

Q5: Does the machine come with a cutting system?

Yes, it features an electric shear that provides clean and precise cuts, eliminating the need for manual trimming.

Q6: How easy is it to operate the machine?

The machine is equipped with a user-friendly PLC control system that allows operators to adjust settings with ease and precision.

Q7: What is the warranty on this machine?

Most manufacturers offer a one-year warranty on parts and labor. However, specific warranty details may vary, so it’s best to confirm with the seller.

Q8: Can the machine be customized for specific profiles?

Yes, the rollers and other components can be customized to produce various profiles based on customer requirements.

Q9: What maintenance does the machine require?

The machine requires regular lubrication, cleaning, and inspection of the rollers and cutting system to ensure optimal performance.

Q10: Is technical support available in Florida?

Yes, technical support and installation services are typically available, especially from local distributors or manufacturers with a presence in the region.

Copyright 2026 © Machine Matcher.