To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

C&Z cold roll forming machines are versatile manufacturing systems designed to produce C and Z purlins, widely used in the construction industry for roofing and wall structures. These machines are known for their precision, efficiency, and adaptability, making them a preferred choice for businesses in Florida's growing construction market.

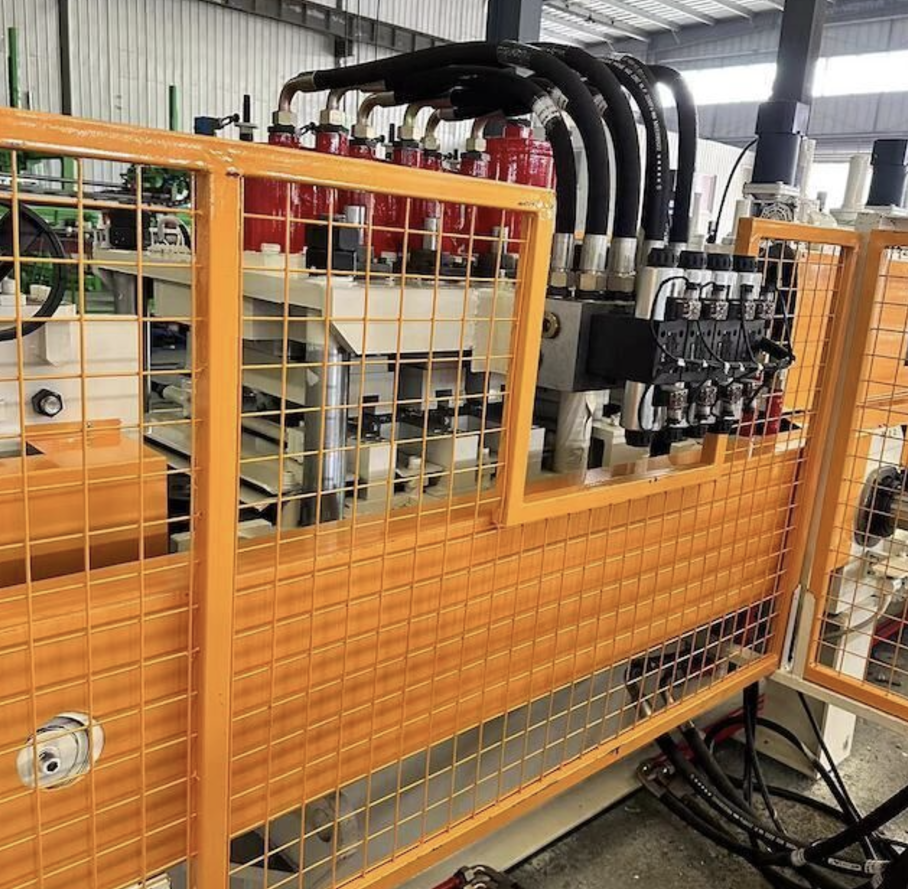

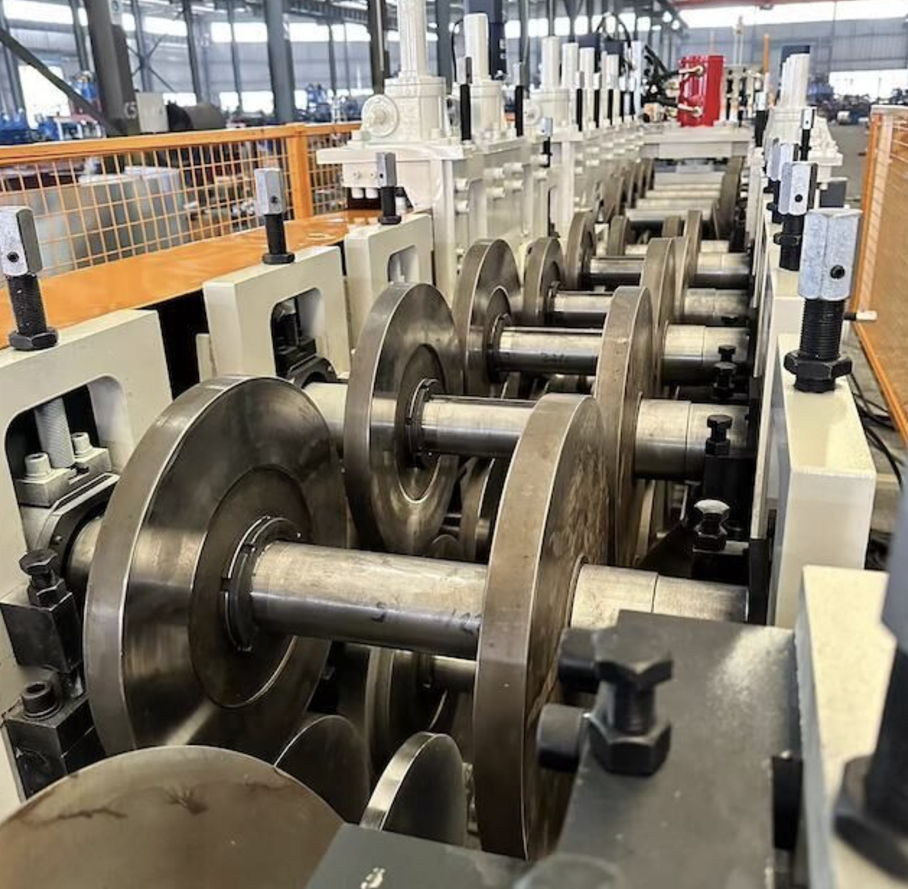

A C&Z cold roll forming machine is a fully automated system capable of producing purlins in both C and Z profiles by adjusting the tooling or rotating the punching system. These machines are engineered for high-speed operation and flexibility, allowing manufacturers to switch between profiles with minimal downtime.

C&Z purlins, produced by these machines, are essential in supporting roof and wall panels, commonly used in warehouses, factories, commercial buildings, and other industrial constructions.

The machine's control system ensures precise dimensions, punching, and cutting, adhering to industry standards and customer requirements. It can handle various materials, including galvanized steel, aluminum, and other high-strength alloys.

| Specification | Details |

|---|---|

| Material Thickness | 1.5mm to 3.0mm |

| Material Width | 80mm to 300mm |

| Material Type | Galvanized steel, mild steel, aluminum |

| Roller Material | High-grade 45# steel with chrome plating |

| Number of Forming Stations | 14-18 stations (varies by model) |

| Forming Speed | 15-25 meters per minute |

| Hydraulic Cutting System | Advanced hydraulic cutter for precision cuts |

| Punching System | Servo-driven hydraulic punching for holes and slots |

| Control System | PLC system with touch-screen interface |

| Profile Sizes | Adjustable to produce C and Z profiles of various sizes |

| Power Requirement | 380V/50Hz/3 Phase (or customized for Florida's standards) |

| Machine Dimensions | Typically 8000mm x 1300mm x 1500mm |

| Weight | Approximately 6,500-8,000 kg |

| Safety Features | Enclosures, emergency stop, overload protection |

In Florida, C&Z roll forming machines are especially valuable for:

Q1. What materials can the C&Z roll forming machine handle?

The machine is designed for galvanized steel, mild steel, and aluminum with thicknesses ranging from 1.5mm to 3.0mm.

Q2. Can the machine be customized for Florida's power supply?

Yes, the machine can be configured for 220V/60Hz or 480V/60Hz to meet Florida's industrial power standards.

Q3. What is the average production speed?

The machine operates at a speed of 15-25 meters per minute, depending on material thickness and complexity.

Q4. Is the machine suitable for large-scale projects?

Absolutely. The high production speed and automation features make it ideal for large-scale industrial and commercial construction projects.

Q5. How long does it take to switch between C and Z profiles?

With hydraulic adjustment, the changeover can be completed in 5-10 minutes.

Q6. What maintenance does the machine require?

Regular lubrication of moving parts, inspection of rollers and cutters, and software updates for the PLC system are essential for optimal performance.

Q7. Can I use this machine for custom purlin profiles?

Yes, the punching and cutting mechanisms can be tailored for unique profiles and dimensions.

Q8. What is the warranty period?

Most manufacturers offer a 1-2 year warranty, covering major components like the PLC system, hydraulic parts, and rollers.

Copyright 2026 © Machine Matcher.