To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

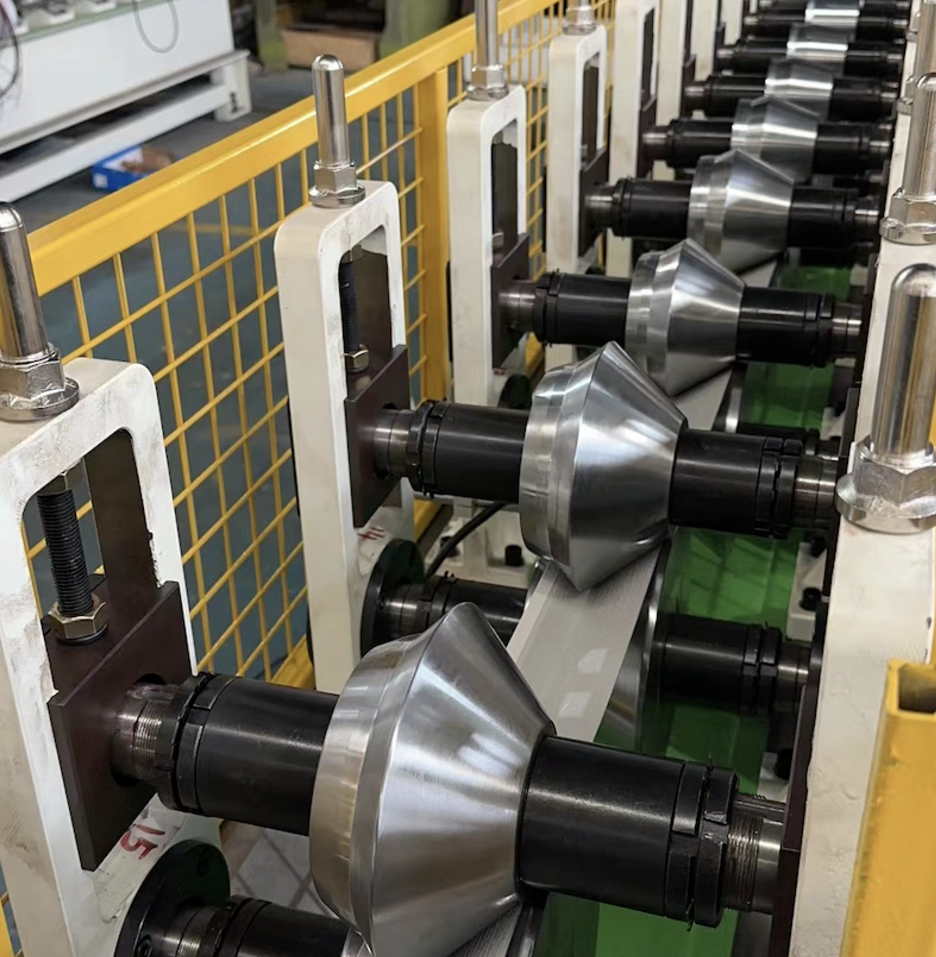

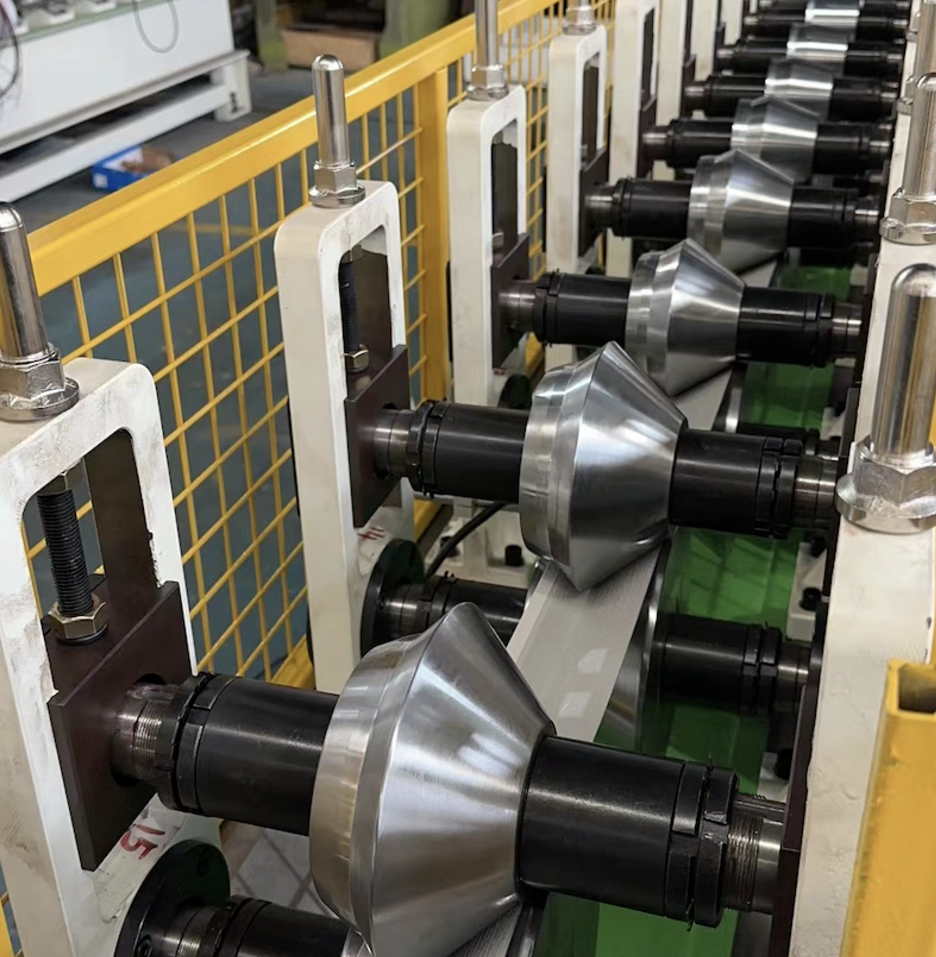

A D-style drip edge cold roll forming machine is a specialized machine designed to manufacture drip edges used in roofing systems. These drip edges are essential for directing water away from the fascia and underlying roofing materials, protecting structures from water damage. The machine produces a precise and consistent D-style profile suitable for various roofing applications. Florida’s unique climate, with frequent rains and hurricanes, makes the demand for quality drip edges particularly high.

The D-style drip edge roll forming machine is engineered to convert metal coils into finished drip edge profiles in a continuous process. This machine offers efficiency, precision, and durability, ensuring consistent production quality. It is ideal for manufacturers and contractors looking to produce high volumes of roofing drip edges tailored to Florida’s roofing market needs.

Key Features:

Q1: What materials can the D-style drip edge roll forming machine process?

A1: The machine processes galvanized steel, aluminum, and coated metals, all of which are suitable for Florida’s climate. These materials are corrosion-resistant and durable.

Q2: How does the machine ensure precision in drip edge profiles?

A2: The machine uses advanced rollers and a PLC system to ensure consistent and accurate profiles. The hydraulic cutting system provides precise cuts without deforming the material.

Q3: Can the machine handle different material thicknesses?

A3: Yes, the machine can process materials with thicknesses ranging from 0.3 mm to 0.8 mm, making it versatile for various roofing requirements.

Q4: Is the machine portable for on-site use in Florida?

A4: The machine is typically stationary, but smaller, portable versions are available for on-site fabrication.

Q5: How does the machine address safety concerns?

A5: Safety features include protective enclosures, emergency stop buttons, and overload protection, ensuring operator safety during use.

Q6: How does the machine accommodate Florida’s roofing styles?

A6: The machine’s adjustable settings and optional pre-punching units allow customization of profiles to suit different roofing designs common in Florida.

Q7: What is the maintenance requirement for this machine in Florida’s humid climate?

A7: Regular cleaning, lubrication of moving parts, and inspection of electrical components are essential to prevent rust and ensure smooth operation.

Q8: How can the machine be integrated into an existing production line?

A8: With its modular design and PLC system, the machine can be seamlessly integrated into existing production setups for continuous manufacturing.

Copyright 2026 © Machine Matcher.