To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

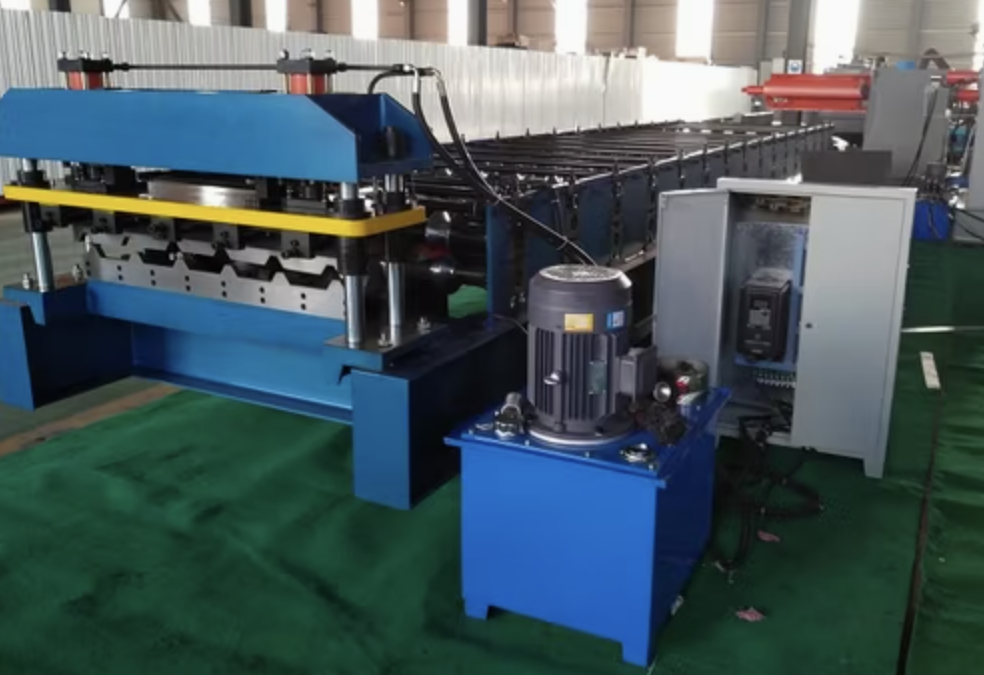

A Galvanized Metal Roofing Roll Forming Machine is an industrial machine specifically designed to produce roofing panels from galvanized steel. These machines are critical in manufacturing high-quality, durable, and weather-resistant metal roofs. The demand for galvanized roofing panels in the USA continues to grow due to their robustness, corrosion resistance, and aesthetic appeal.

These machines are commonly used in industries such as construction, infrastructure development, and agriculture. They are versatile and can be customized to produce various profiles, such as standing seam, corrugated sheets, and PBR panels, catering to the diverse requirements of the American market.

Below are the typical specifications for a standard galvanized metal roofing roll forming machine:

A galvanized metal roofing roll forming machine transforms flat metal coils into finished roofing profiles through a continuous bending process. The machine operates by feeding the galvanized steel coil into the system, where it passes through a series of precision rollers that shape it into the desired profile.

The machine is designed for seamless operation, with an integrated PLC system that ensures precise dimensions and minimizes material wastage. The hydraulic cutting mechanism provides clean and accurate cuts, essential for proper installation on roofing projects.

Q1: What is the delivery time for a galvanized metal roofing roll forming machine in the USA?

A: Delivery typically ranges from 45 to 60 days, depending on customization requirements and shipping conditions.

Q2: Can the machine be adapted for US power requirements?

A: Yes, the machine can be configured for 220V or 480V, 60Hz, which are common power standards in the USA.

Q3: How much space is needed to set up the machine?

A: A typical setup requires approximately 20–30 feet of length and 8–10 feet of width, depending on the model.

Q4: What maintenance is required for the machine?

A: Regular lubrication of rollers, checking hydraulic fluid levels, and cleaning the system after production are recommended to ensure long-term performance.

Q5: What profiles can this machine produce?

A: The machine can produce profiles like standing seam panels, corrugated sheets, and PBR panels, depending on the configuration.

Q6: Are training and installation services available?

A: Yes, manufacturers usually offer training sessions and installation assistance to ensure smooth operation.

Q7: What is the price range for a galvanized metal roofing roll forming machine?

A: Prices typically range from $30,000 to $100,000, depending on machine features, profile complexity, and speed options.

Copyright 2026 © Machine Matcher.