To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

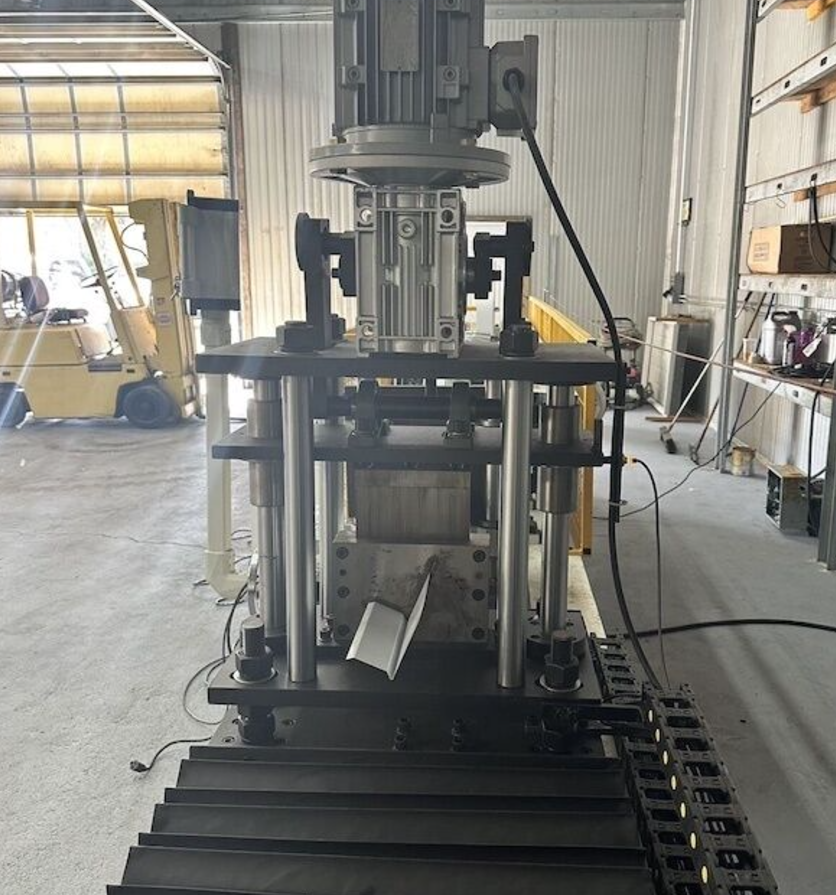

A Galvanized Steel Drip Edge Roll Forming Machine is a high-precision, automated system designed to produce drip edge profiles from galvanized steel. These profiles are commonly used in roofing applications to guide water away from roof edges, preventing water damage to walls and foundations. The machine is tailored to meet the needs of Florida's construction and roofing industries, taking into account the state's climate challenges such as heavy rainfall and hurricanes.

This machine ensures consistent quality, high-speed production, and minimal waste, making it ideal for large-scale operations. It is engineered for durability and can handle varying thicknesses of galvanized steel with ease.

Q1: What is the primary material used in the machine, and why?

A: The machine uses galvanized steel because it offers excellent corrosion resistance, which is crucial in Florida's humid and salty coastal environments.

Q2: Can the machine handle different profile sizes?

A: Yes, the machine is customizable and can produce drip edge profiles in various widths and shapes to meet specific project requirements.

Q3: What is the production speed of the machine?

A: The standard production speed is 15–30 meters per minute, but high-speed models can achieve up to 50 meters per minute.

Q4: Is it suitable for small businesses or only for large-scale manufacturers?

A: The machine is versatile and can be configured for both small-scale and large-scale operations, depending on the budget and production needs.

Q5: What maintenance is required?

A: Regular lubrication of moving parts, inspection of rollers and cutters for wear, and software updates for the PLC system ensure optimal performance.

Q6: Does the machine come with training and support?

A: Yes, most suppliers provide on-site installation, training, and ongoing technical support to ensure smooth operations.

Q7: How does this machine compare to other roofing profile machines?

A: The Galvanized Steel Drip Edge Roll Forming Machine is specifically designed for drip edge profiles, offering specialized precision and efficiency compared to general-purpose roofing machines.

Copyright 2026 © Machine Matcher.