To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

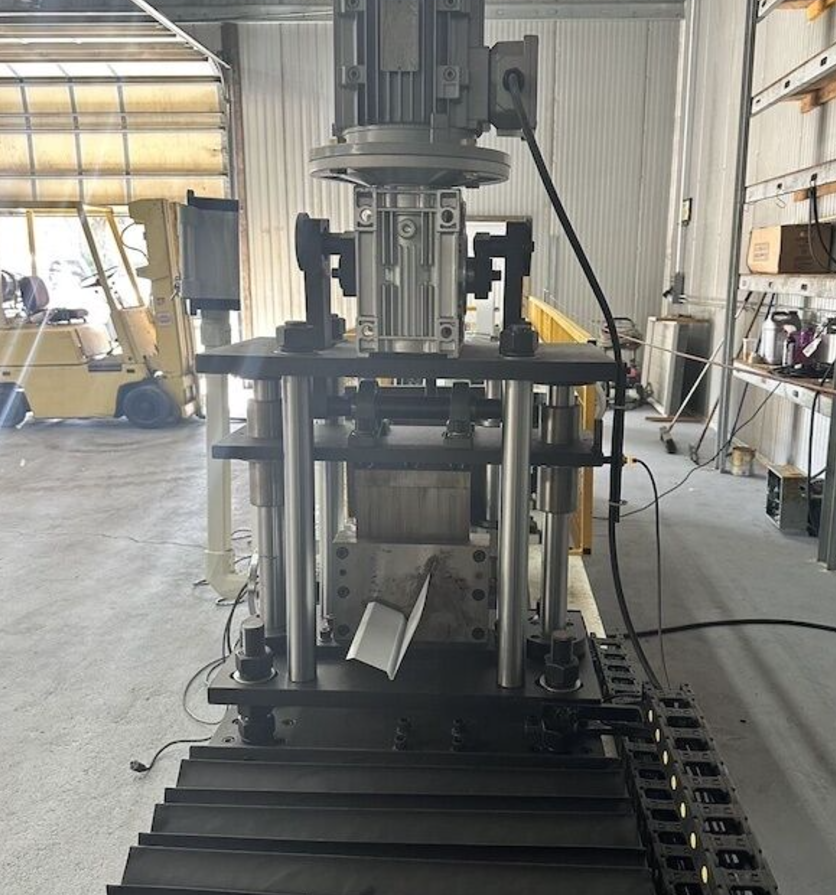

A Metal Roof Drip Edge Roll Forming Machine is a specialized piece of equipment designed to produce drip edge profiles efficiently and accurately for metal roofing applications. Drip edges are critical components in roofing systems, ensuring water runs off smoothly and preventing damage to the roof deck and underlying structures. This machine automates the process of fabricating precise drip edge profiles, enhancing production speed and consistency.

The machine is ideal for use in roofing manufacturing facilities, particularly in areas like Florida, where extreme weather conditions demand high-quality roofing solutions. It can handle various materials such as aluminum, galvanized steel, and stainless steel, catering to the diverse needs of the roofing industry.

Q1: What materials can this machine handle?

The machine can process aluminum, galvanized steel, and stainless steel with a thickness range of 0.3 mm to 0.8 mm.

Q2: Is this machine suitable for Florida’s roofing market?

Yes, the machine is highly suitable for Florida’s roofing market. It produces precise drip edges that are essential for protecting buildings from heavy rain, storms, and hurricanes common in the region.

Q3: Can the machine be customized?

Yes, the machine can be customized for specific profile designs, material types, and production speeds.

Q4: How does the machine ensure cutting precision?

The hydraulic cutting system uses Cr12Mov steel blades, which are heat-treated for durability and sharpness, ensuring precise cuts every time.

Q5: What is the production speed of the machine?

The standard production speed is 10-15 meters per minute, but higher speeds can be achieved with advanced configurations.

Q6: Is it easy to operate?

Yes, the machine features a PLC control system with a user-friendly interface, making it easy to operate and manage.

Q7: Can it produce multiple drip edge designs?

Yes, with the appropriate rollers and configurations, the machine can produce various drip edge designs.

Q8: What optional features are available?

Optional features include stackers, punching systems, leveling systems, and remote PLC controls for enhanced functionality.

Q9: What are the maintenance requirements?

Regular maintenance involves lubricating moving parts, checking the alignment of rollers, and ensuring the cutting blades are sharp. Detailed instructions are provided with the machine.

Q10: How long does it take to set up the machine?

The setup typically takes 1-2 days, depending on the complexity of the configuration and the availability of required tools and materials.

Copyright 2026 © Machine Matcher.