To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

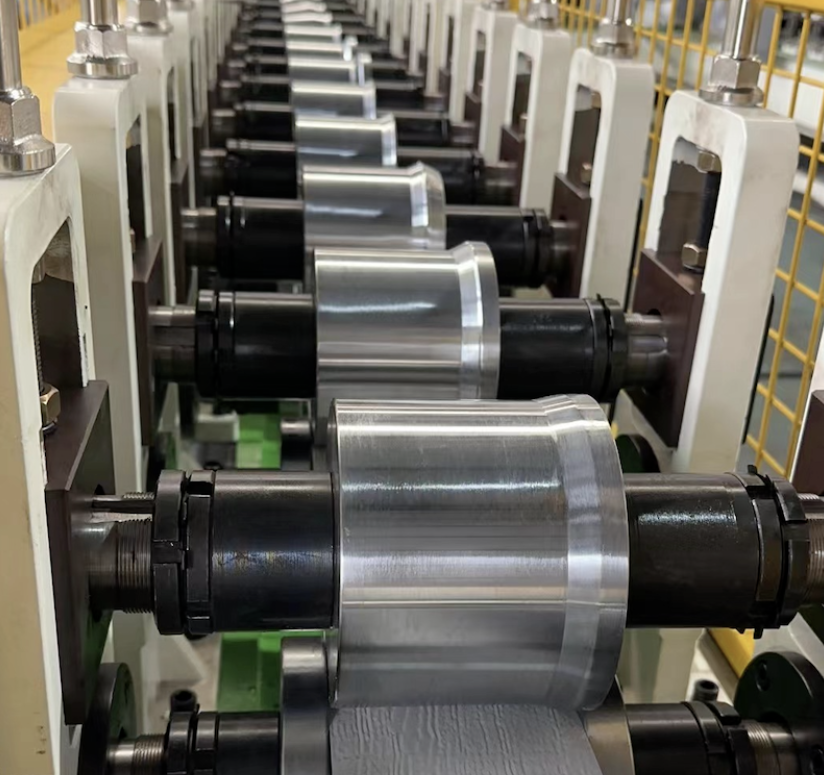

The Metal Roof Drip Edge Roll Forming Machine is a specialized industrial equipment designed to produce high-precision drip edge profiles for metal roofing systems. Drip edges are crucial for protecting roof edges by directing water away from the fascia and underlying roofing materials. This machine is engineered to produce profiles efficiently, consistently, and in compliance with industry standards in the USA.

The machine is versatile, offering customization for profile dimensions, materials, and thicknesses to cater to the diverse needs of contractors, builders, and manufacturers. Its user-friendly interface, robust design, and high-speed production capabilities make it ideal for small to large-scale operations.

1. What materials can the Metal Roof Drip Edge Roll Forming Machine process?

This machine can process aluminum, galvanized steel, and pre-coated steel, with material thickness ranging from 0.3mm to 1.2mm.

2. Can the machine be customized for specific drip edge profiles?

Yes, the machine is highly customizable to produce various profile dimensions and designs according to customer requirements.

3. What is the typical production speed of the machine?

The production speed ranges from 10 to 20 meters per minute, adjustable based on the complexity of the profile.

4. How energy-efficient is the machine?

The machine features energy-efficient motors and hydraulic systems designed to minimize power consumption while ensuring optimal performance.

5. Does the machine comply with USA safety standards?

Yes, the machine is equipped with safety guards, emergency stops, and complies with OSHA and other relevant safety standards in the USA.

6. Is remote operation available?

Yes, the machine comes with a PLC system that supports remote operation for monitoring and adjustments.

7. What additional components can be added to the machine?

Optional extras include automatic stackers, coil car tippers, remote PLC systems, and manual or hydraulic uncoilers.

8. What are the maintenance requirements?

Regular maintenance includes lubricating the rollers, inspecting the hydraulic system, and ensuring the PLC system is updated. Detailed maintenance instructions are provided with the machine.

9. How can I ensure the machine meets my production needs?

You can share your required profile dimensions, materials, and production volume with the manufacturer for a customized solution.

10. What is the delivery and installation process?

The machine is shipped with installation instructions. On-site installation and training services are available upon request.

The Metal Roof Drip Edge Roll Forming Machine is a valuable asset for roofing contractors and manufacturers in the USA. With its precision, efficiency, and adaptability, it helps streamline the production of high-quality drip edges, ensuring durability and aesthetics in roofing projects.

Copyright 2026 © Machine Matcher.