To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

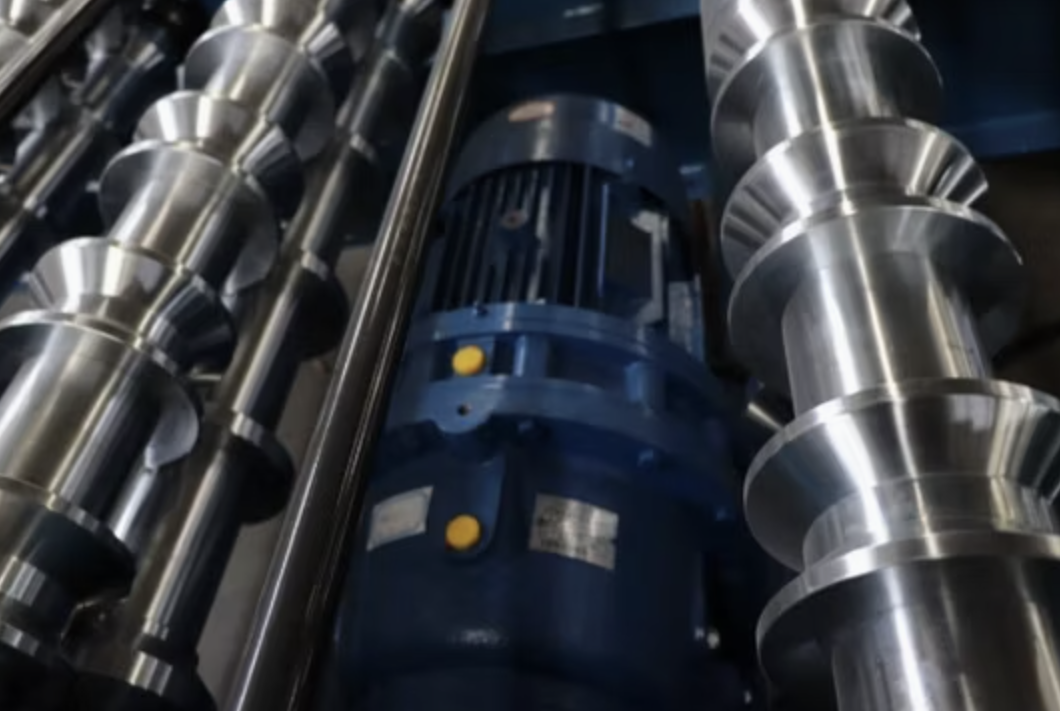

The Pro Rib Metal Roofing Roll Forming Machine is a specialized piece of industrial equipment designed for the efficient production of Pro Rib metal roofing panels. These panels are widely used in commercial, residential, and industrial construction due to their durability, aesthetic appeal, and cost-effectiveness. This guide covers the machine’s description, specifications, and a detailed question-and-answer section tailored for the U.S. market.

The Pro Rib Metal Roofing Roll Forming Machine is engineered for precision, speed, and reliability. It is capable of producing Pro Rib profiles with consistent accuracy, ensuring high-quality output suitable for various applications. The machine incorporates advanced automation and robust components to handle different types of materials, including galvanized steel, aluminum, and pre-painted steel.

Key Features:

1. What materials can the Pro Rib Metal Roofing Roll Forming Machine handle?

The machine can process galvanized steel, aluminum, and pre-painted steel coils with thicknesses ranging from 0.3mm to 0.8mm, which are standard materials for Pro Rib roofing panels in the U.S.

2. What is the typical output speed of this machine?

The machine can produce panels at speeds of up to 30 meters per minute, making it suitable for high-volume production.

3. Can this machine produce custom panel sizes?

Yes, the machine’s adjustable rollers and PLC system allow for the customization of panel widths and rib heights according to specific requirements.

4. What are the power requirements for U.S. operations?

The machine is compatible with U.S. electrical standards, typically operating on 220V/60Hz or 380V/60Hz power supplies. Ensure you specify the required voltage when ordering.

5. Is training provided for machine operation?

Yes, most suppliers provide on-site or remote training for operators, covering setup, maintenance, and troubleshooting.

6. What maintenance is required for the machine?

Regular maintenance includes:

7. Does the machine come with a warranty?

Typically, the machine includes a 12-month warranty covering manufacturing defects. Additional extended warranties may be available from the supplier.

8. How is shipping and installation handled in the U.S.?

Machines are shipped in secure crates and typically require professional installation by technicians provided by the supplier. Installation includes setup, calibration, and initial training.

9. Are spare parts readily available?

Yes, reputable suppliers ensure that spare parts like rollers, blades, and motors are available for purchase and quick delivery within the U.S.

10. What industries use Pro Rib roofing panels?

Pro Rib panels are popular in construction, agriculture, and industrial projects, including barns, warehouses, garages, and residential roofing.

Copyright 2026 © Machine Matcher.