To express an interest in this machine please submit the form below.

Not Sure What Machine You Need?

Select Your Profile, We'll Match It

Choose your desired profile drawing, and let Machine Matcher connect you with the best roll forming machine tailored to your needs.

Browse Profiles

Ridge cap roll forming machines are vital for roofing solutions, especially in the United States where roofing projects demand high precision and durability. These machines are specifically designed to produce ridge caps, an essential component for sealing and protecting the roof's peak from water, debris, and environmental elements. Ridge caps are widely used in residential, commercial, and industrial buildings.

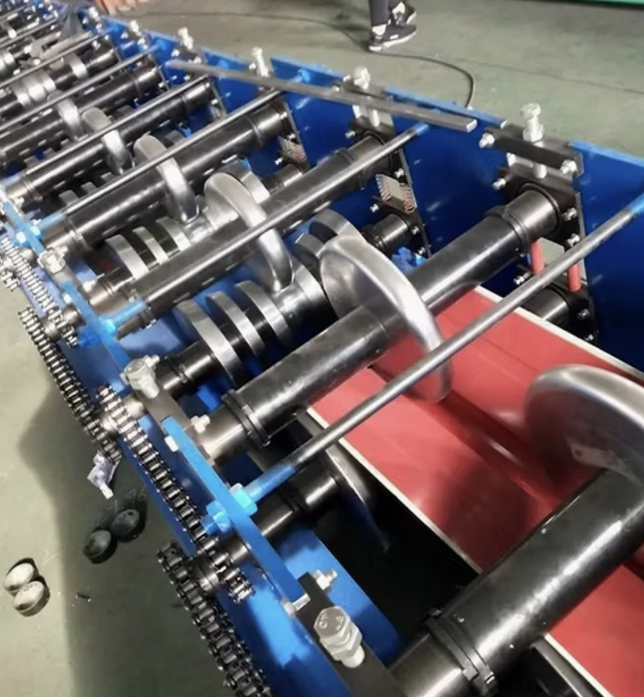

A ridge cap roll forming machine is a specialized piece of equipment that transforms metal coils into ridge cap profiles. The process involves uncoiling, leveling, feeding, roll forming, and cutting to length. These machines are engineered to work with various materials such as galvanized steel, aluminum, or pre-painted steel, ensuring high-quality and durable roofing components.

Modern ridge cap roll forming machines incorporate advanced technology, such as PLC systems and hydraulic cutting, to ensure precision and efficiency. They can be customized to produce a range of ridge cap profiles based on customer requirements.

These machines can process materials such as galvanized steel, aluminum, copper, and pre-painted steel. The material choice depends on the specific application and desired aesthetics.

Machines are tailored to meet U.S. standards with specific voltage settings (e.g., 220V or 480V) and profile designs commonly used in American roofing projects.

Regular maintenance includes lubrication of moving parts, checking hydraulic oil levels, cleaning rollers, and inspecting the cutting blades for wear and tear. This ensures the machine operates efficiently and prolongs its lifespan.

Yes, the machine can be customized to produce various ridge cap profiles by adjusting the roller dies and PLC settings.

Prices range from $30,000 to $80,000 depending on the machine’s specifications, customization, and optional features.

Copyright 2026 © Machine Matcher.